Disclaimer

How to change wheel bearing on a car – replacement tutorial

downloads:

4117

Views:

24393

Wheel bearing repair [AUTODOC TUTORIAL]

Flat screwdriver

Tap wrench

Wheel impact socket

Impact socket

Ceramic grease

Brake cleaner

Jack

Line stoppers

Circlip pliers

Please note!

- The wheel bearing allows the wheel hub to be mounted, aligned, and rotate freely on the axle

- A typical sign of wheel bearing failure is a humming noise that gets louder when turning

- 1.

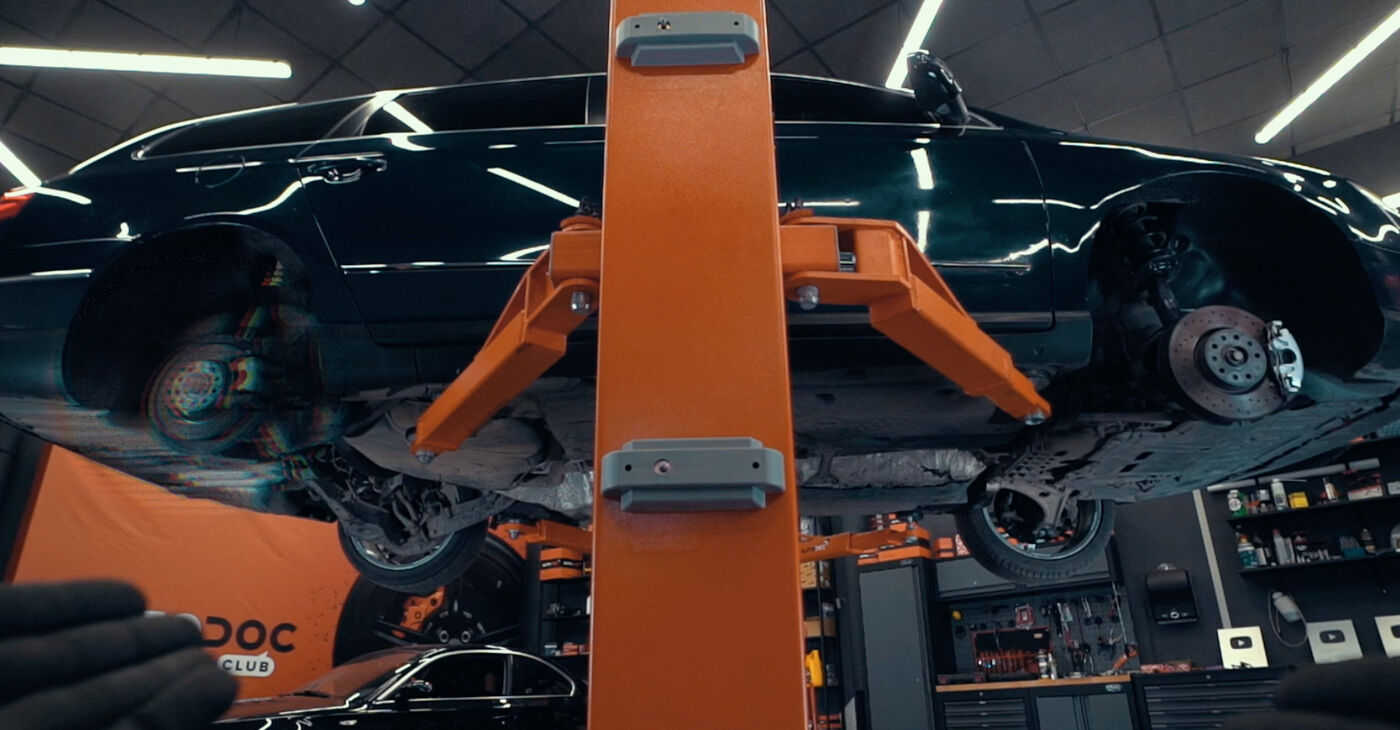

Lift up the car using a jack, jack stands, and wheel chocks; Or use a car lift

Lift up the car using a jack, jack stands, and wheel chocks; Or use a car lift - 2.

Remove the wheel and any parts of the brake system that obstruct access to the bearing

Remove the wheel and any parts of the brake system that obstruct access to the bearing - 3.

Familiarise yourself with the bearing’s designThere are several types of wheel hub bearingsSingle row ball bearings and tapered roller bearings (GEN-0)Dual row bearings (GEN-1)Bearings equipped with a flange with mounting holes (GEN-2)Wheel hub assembly (GEN-3)

Familiarise yourself with the bearing’s designThere are several types of wheel hub bearingsSingle row ball bearings and tapered roller bearings (GEN-0)Dual row bearings (GEN-1)Bearings equipped with a flange with mounting holes (GEN-2)Wheel hub assembly (GEN-3) - 4.

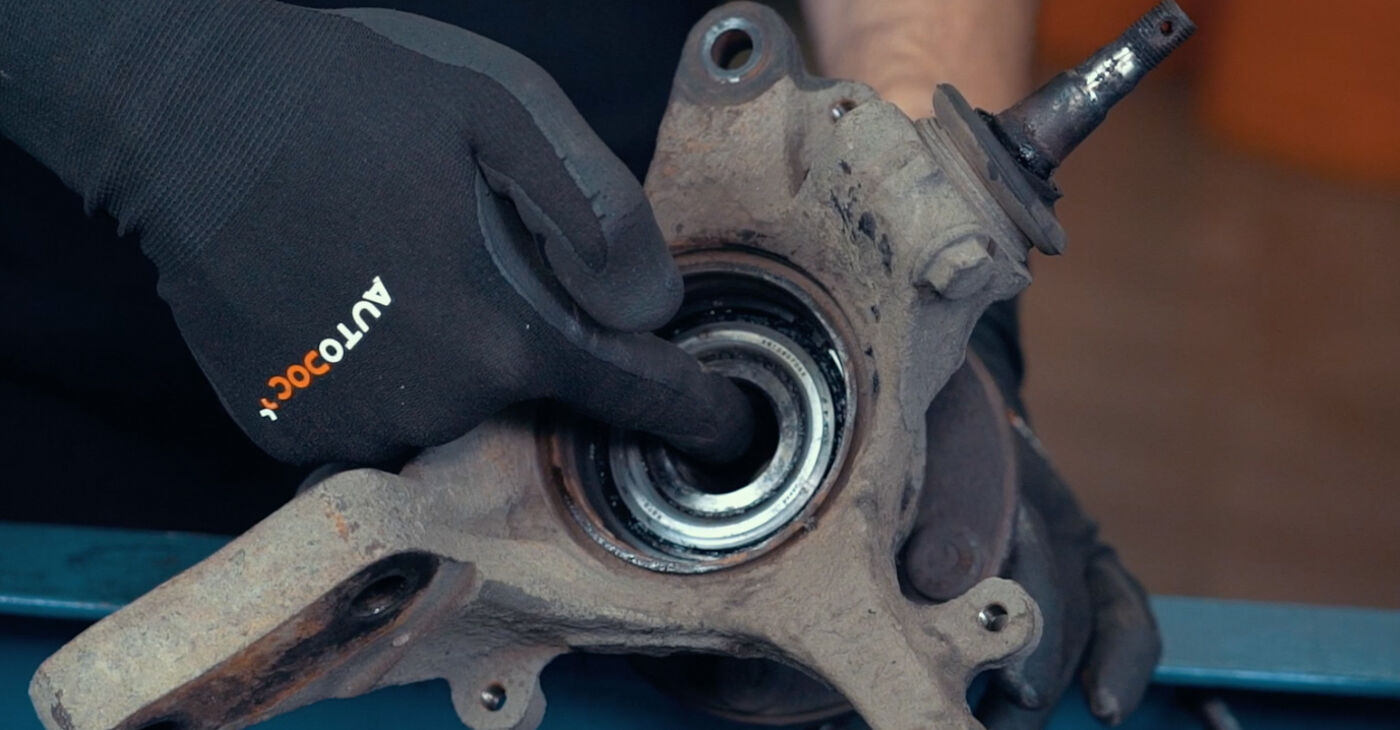

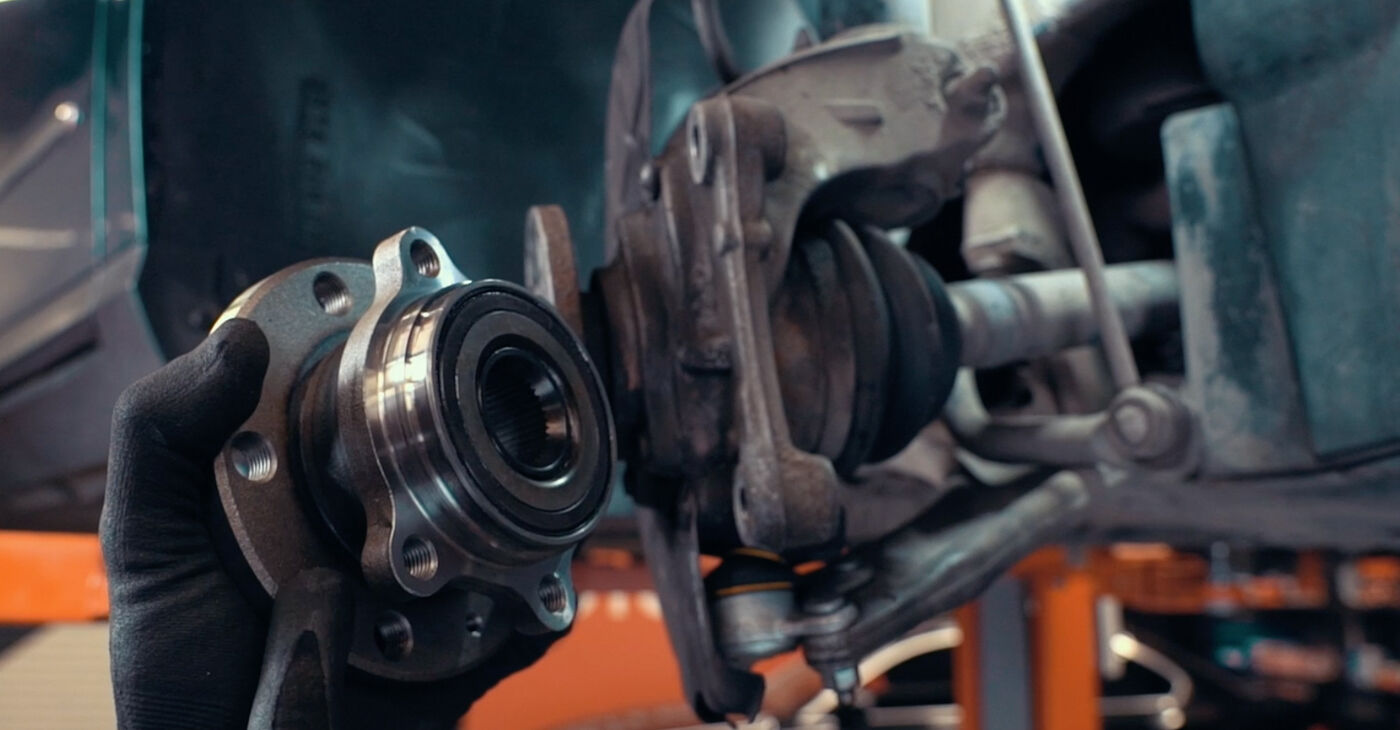

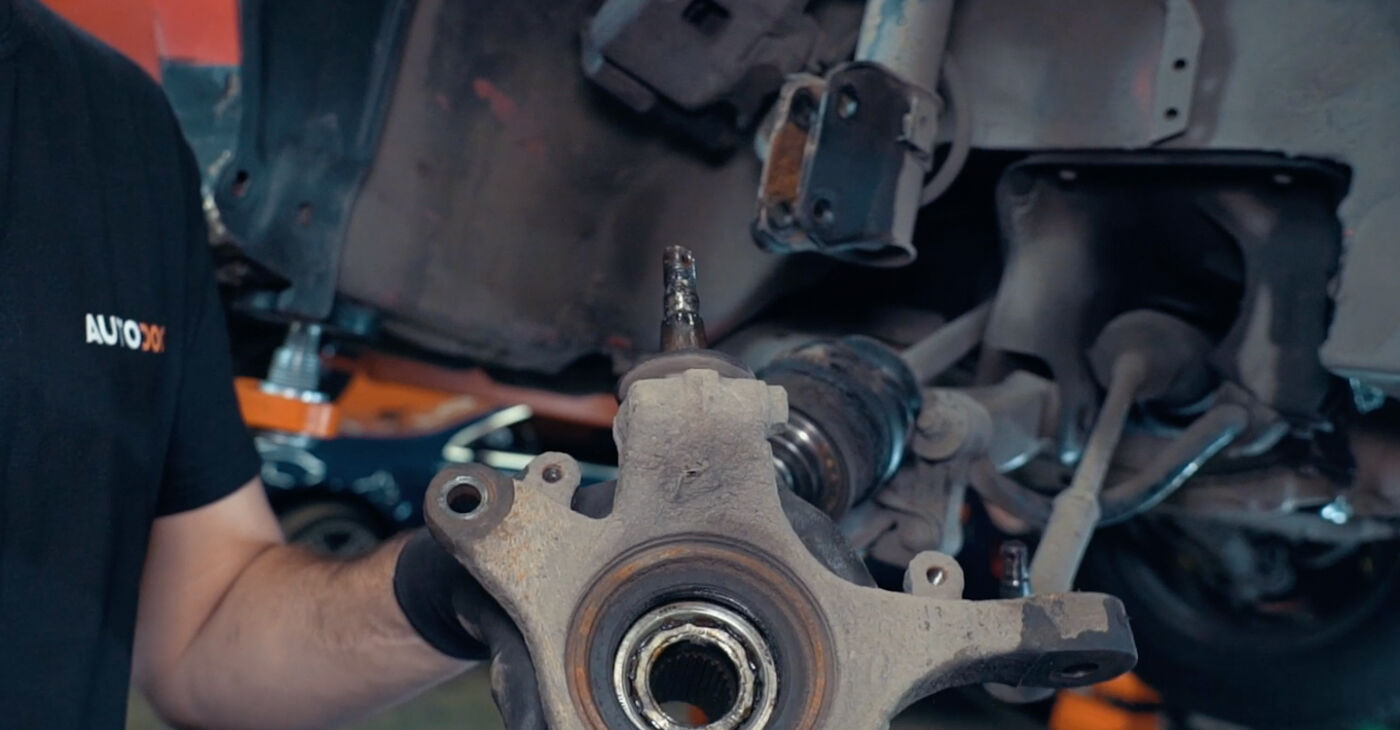

The wheel hub bearing assembly (GEN-3) on the drive axle is attached to the steering knuckle

The wheel hub bearing assembly (GEN-3) on the drive axle is attached to the steering knuckle - 5.

In order to access its fasteners you need to disconnect the CV axleAUTODOC experts recommend:The CV axle fastener is easier to unscrew with the car on its wheels

In order to access its fasteners you need to disconnect the CV axleAUTODOC experts recommend:The CV axle fastener is easier to unscrew with the car on its wheels - 6.

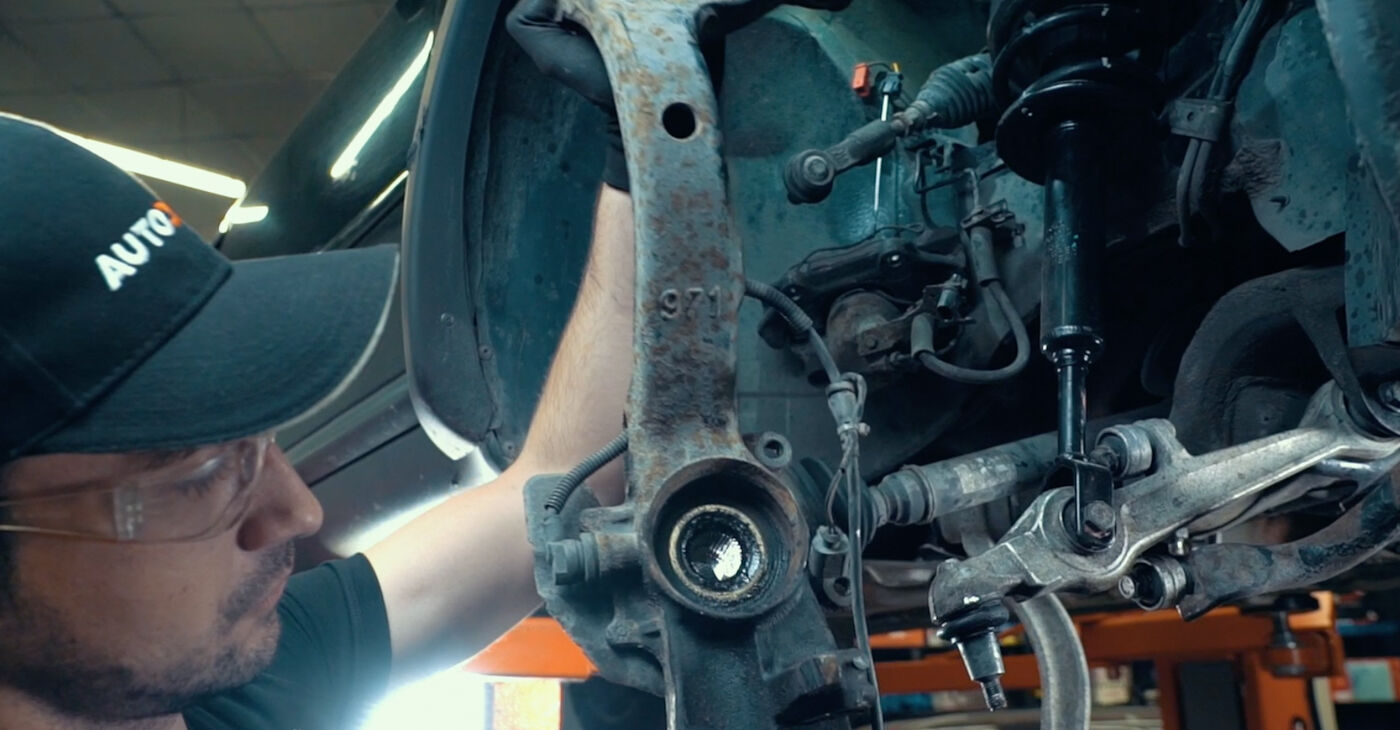

Depending on the car design it may be necessary to dismount the complete steering knuckle

Depending on the car design it may be necessary to dismount the complete steering knuckle - 7.

It needs to be disconnected from the suspension strut, control arms, and steering components

It needs to be disconnected from the suspension strut, control arms, and steering components - 8.

Disconnect the ball joint and the CV axle

Disconnect the ball joint and the CV axle - 9.

Move the CV axle aside

Move the CV axle aside - 10.

Use a jack to support the steering knuckle or attach it to the ball joint

Use a jack to support the steering knuckle or attach it to the ball joint - 11.

Clean all fastenersAUTODOC recommends:Tap the fasteners with a hammer to make them easier to unscrew

Clean all fastenersAUTODOC recommends:Tap the fasteners with a hammer to make them easier to unscrew - 12.

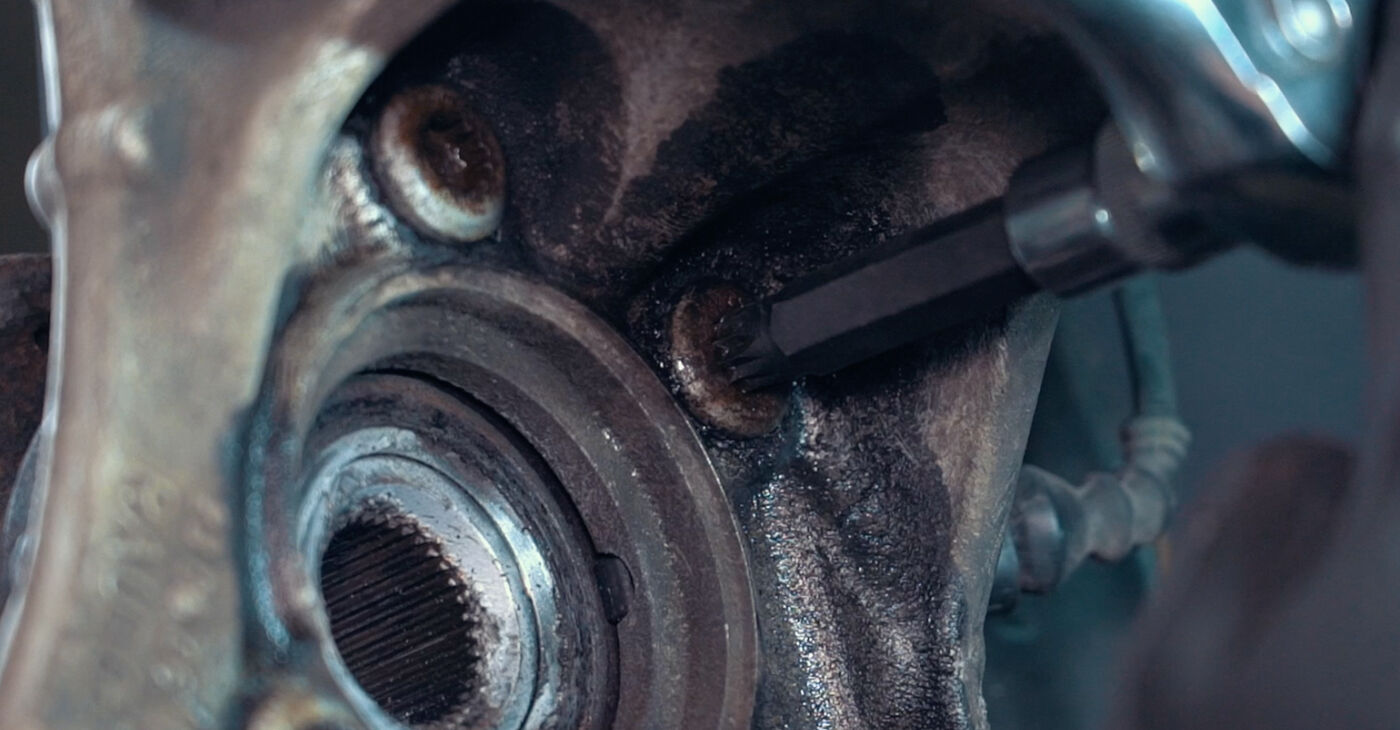

Unscrew the wheel hub bearing fastener

Unscrew the wheel hub bearing fastener - 13.

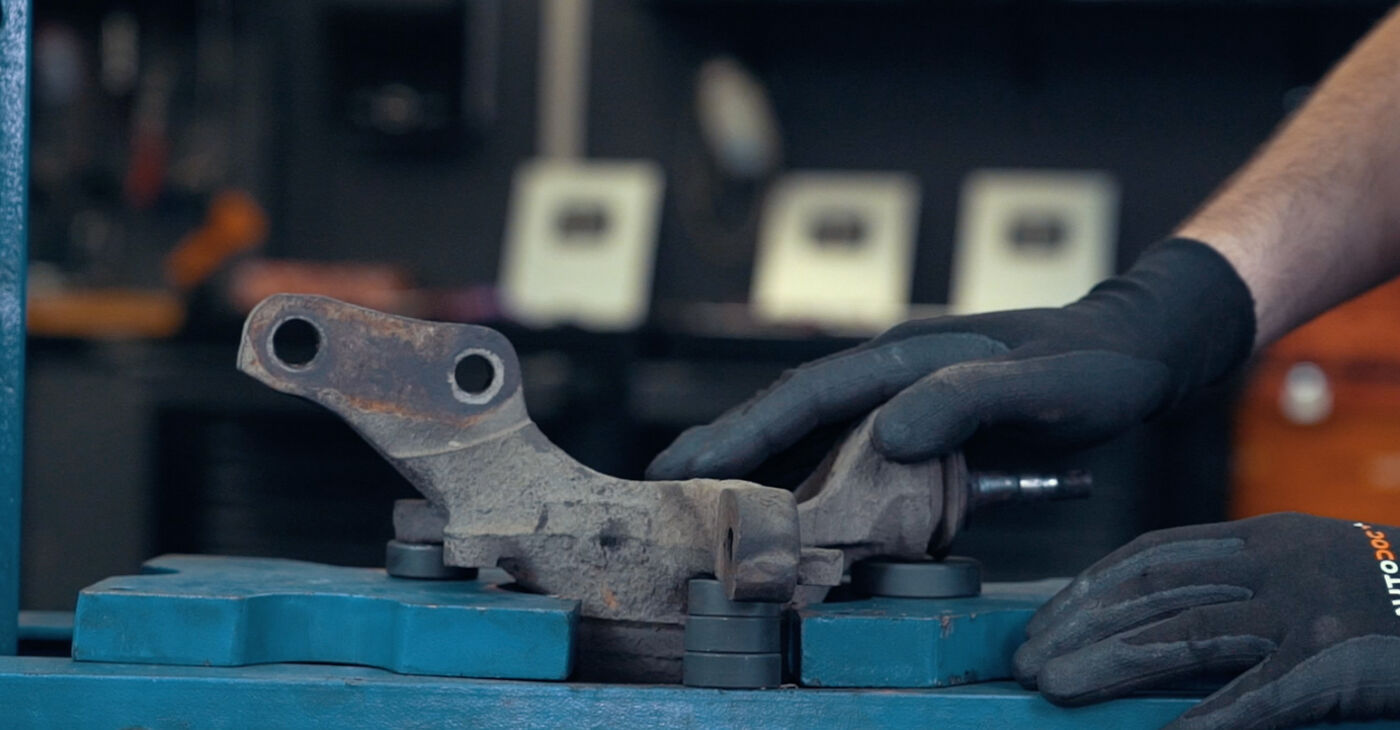

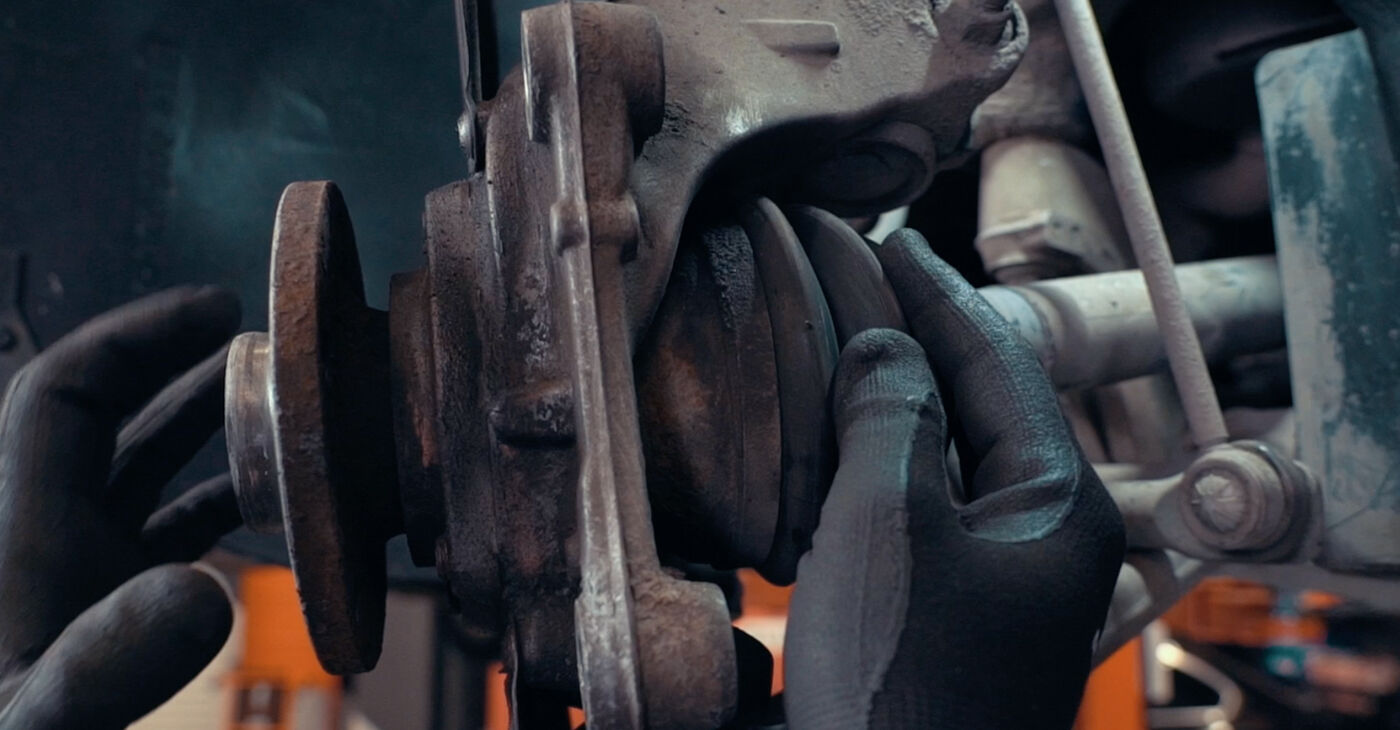

Remove the bearing from its seat on the steering knucklePlease note!If removal is difficult, additional tools may be required

Remove the bearing from its seat on the steering knucklePlease note!If removal is difficult, additional tools may be required - 14.

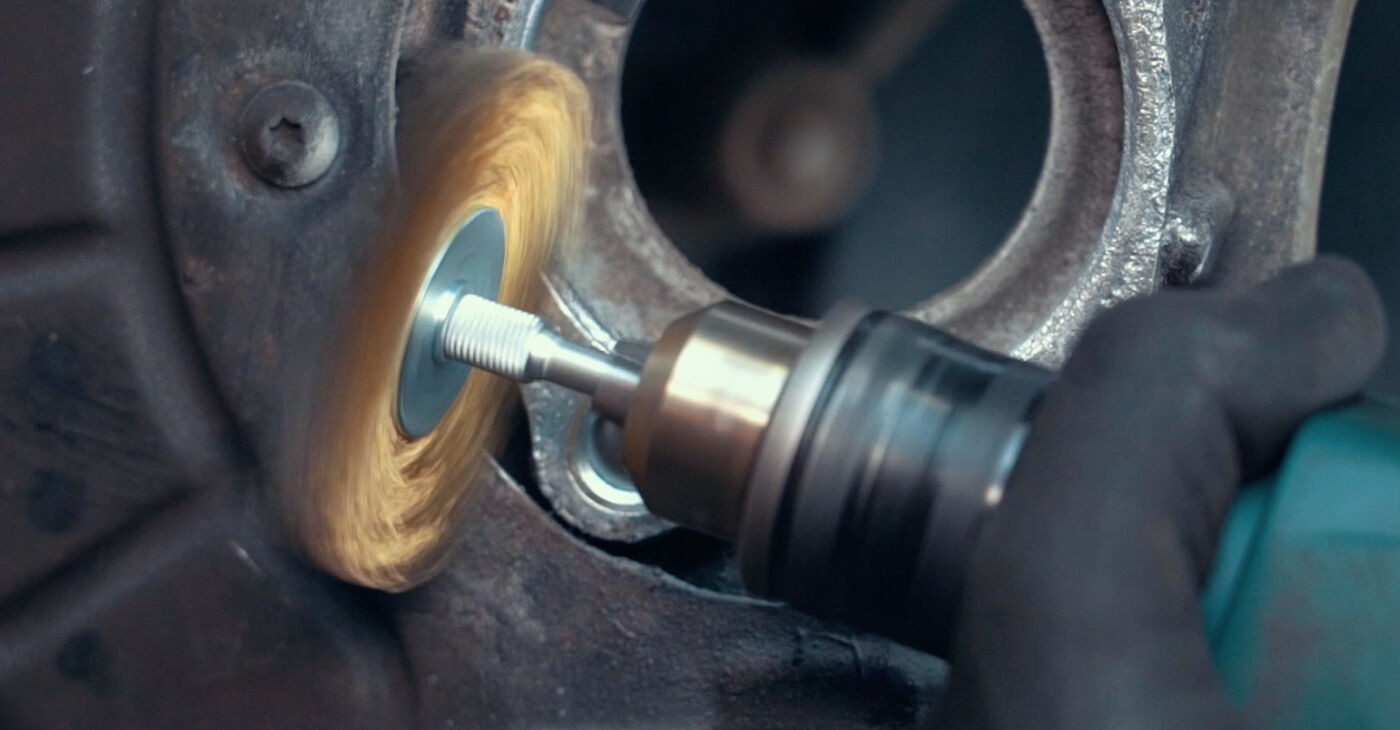

Clean the mounting seats

Clean the mounting seats - 15.

Proceed carefully, especially if there is an ABS sensor

Proceed carefully, especially if there is an ABS sensor - 16.

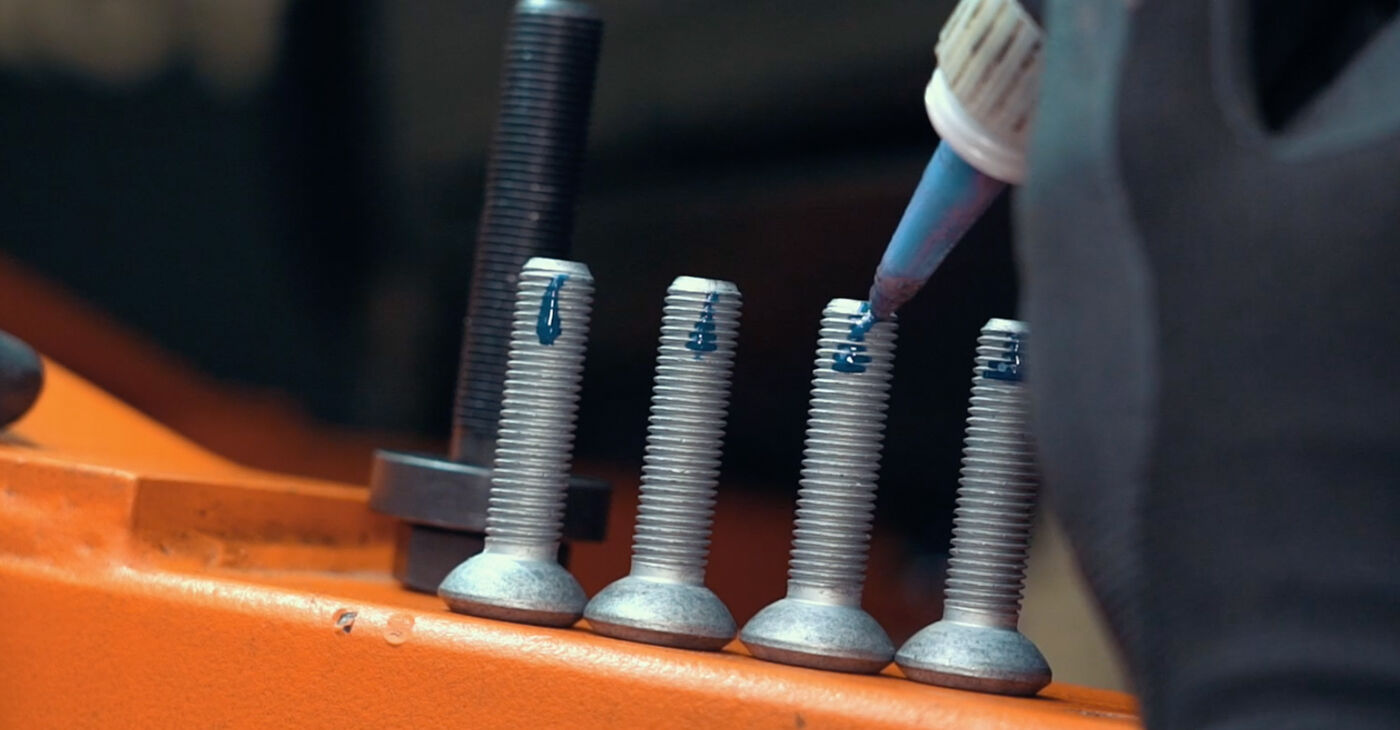

Be sure to use new fasteners

Be sure to use new fasteners - 17.

Coat the mounting surface of the bearing with a corrosion inhibitor

Coat the mounting surface of the bearing with a corrosion inhibitor - 18.

Tighten the bolts one by one, crosswise

Tighten the bolts one by one, crosswise - 19.

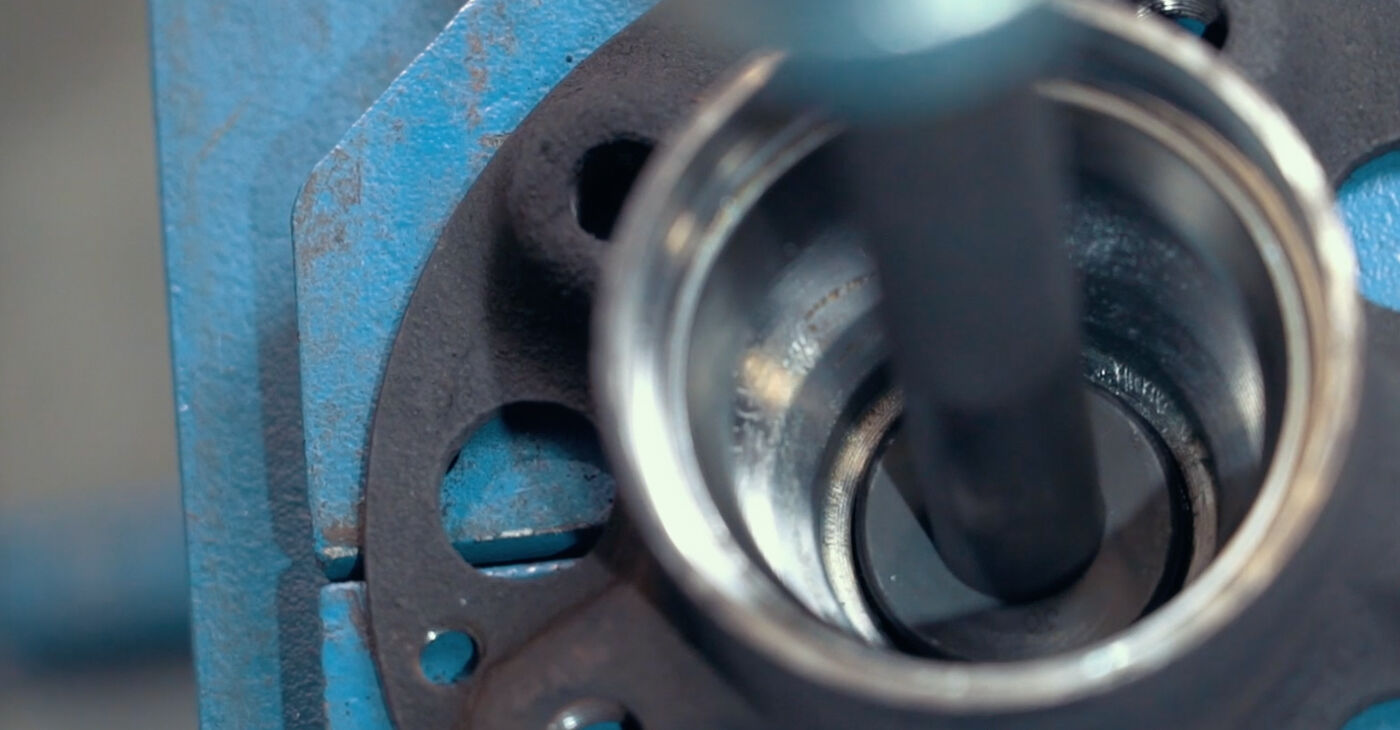

A GEN-2 (flange) bearing is normally fitted in the wheel hub, which is mounted to the axleImportant!A special puller may be needed to remove the bearing from the axle

A GEN-2 (flange) bearing is normally fitted in the wheel hub, which is mounted to the axleImportant!A special puller may be needed to remove the bearing from the axle - 20.

Clean the hub bearing mounting seat

Clean the hub bearing mounting seat - 21.

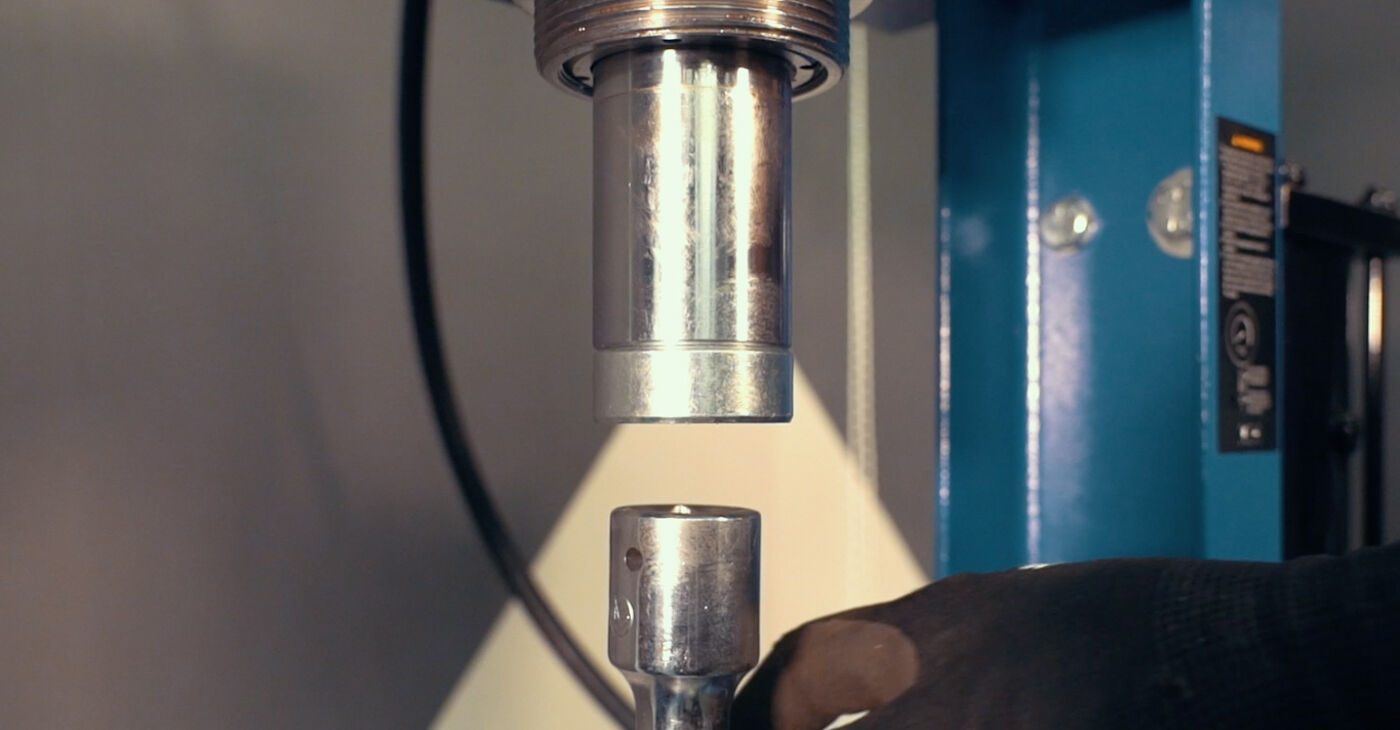

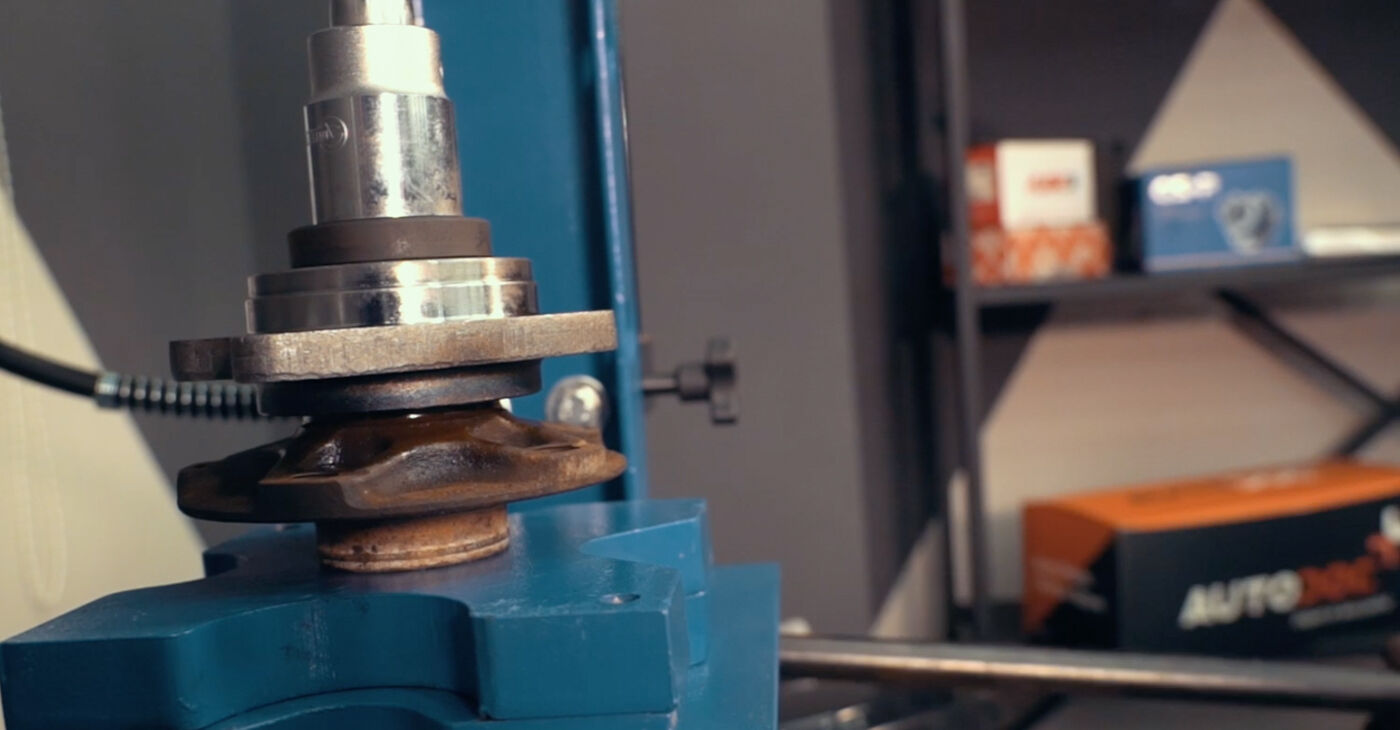

When installing this type of bearing, you should only exert force on the inner ring

When installing this type of bearing, you should only exert force on the inner ring - 22.

If the bearing is mounted on one of the drive wheels, it is necessary to dismount the wheel hub bearing assembly

If the bearing is mounted on one of the drive wheels, it is necessary to dismount the wheel hub bearing assembly - 23.

In this case, the bearing is attached to the steering knuckle. The wheel hub needs to be pressed out of it

In this case, the bearing is attached to the steering knuckle. The wheel hub needs to be pressed out of it - 24.

Replacing the double row bearing (GEN-1) requires dismounting the steering knuckle

Replacing the double row bearing (GEN-1) requires dismounting the steering knuckle

Was this manual helpful?

Please rate this manual on a scale from 1 to 5. If you have any questions, feel free to ask us.

Users voted – 1

Unlock your car maintenance assistant!

Track expenses, manage logs, schedule replacements, and more.

Popular Suspension and Arms maintenance tutorials

Top auto repair manuals

Time to replace parts? Get even better deals in our Shop app.

SCAN ME