The ins and outs of discs, drums, shoes, and hydraulics: how your brakes keep you safe.

Brakes are just as important as the engine for any car and they’re vital for keeping you safe when driving.

The basic principle of brakes is simple: they take kinetic energy from the moving vehicle and transfer it to heat energy through friction to make the car come to a stop.

All brakes follow the same principle, but different systems achieve this friction in different ways.

There are lots of factors that are going to determine what type of system your car has and what components it uses as all systems vary slightly, but here are the systems your car is likely to have, how they work, and what the key components of them are likely to be. Understanding the braking system on a car and braking systems in vehicles can be vital, so read on!

Braking system components

Before getting on to what type of systems a car can use to brake, it’s worth mentioning the key components, especially if you are thinking about repairing or replacing braking system parts. The types of parts your brake system uses will often depend on the make and model of the car, the speeds it can achieve, the price of the car, and how old it is. A brake system will either use a drum or a disc and will contain brake pads.

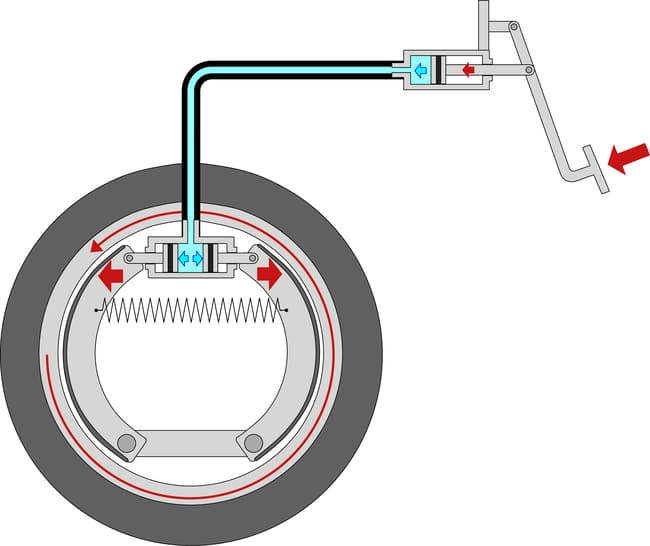

Drum Brakes

Drum brakes are the oldest way of bringing a car to a stop. A drum is attached to the inside of the wheel and inside are two heat resistant pads. When the pedal is pressed, the pads push outwards and squeeze the drum and the drum stops the wheel. The friction caused between the pads and the drum causes kinetic energy to be transferred to heat energy.

These types of brakes were used commonly on cars up until the 1980s. As cars began to get more powerful, drum brakes weren’t up to the challenge of stopping them. They get very hot under intense conditions of frequent braking and if they’re too hot they can’t change the energy of motion into heat and they stop working. After the 1980s, many cars began to use disc brakes instead.

This is not to say, however, that drum brakes don’t get used at all. They are still adequate and they do the job. They are often used for rear wheel brakes, as when a car stops most of the pressure is applied to the front brakes. Since drum brakes are cheaper to make and simpler to maintain, they are often used on entry level cars or cheaper models.

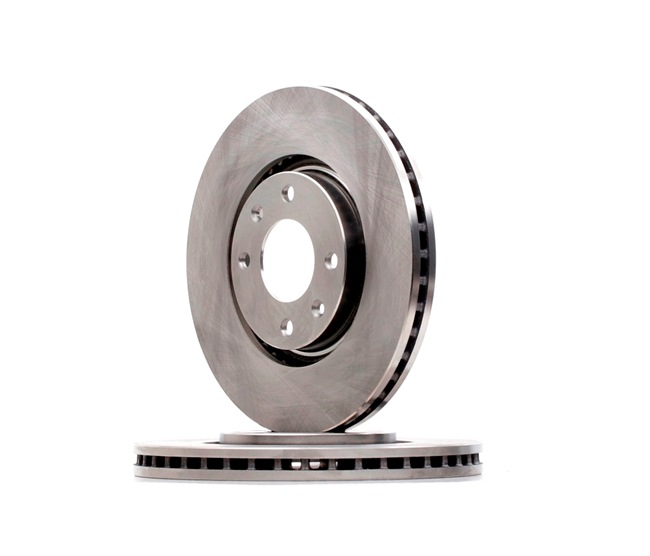

Disc brakes

Disc brakes are what ‘replaced’ drum brakes as the most popular choice for most cars. Drum brakes push out and this doesn’t create as much pressure as squeezing in on the wheel. So experts designed a system where something is squeezed rather than pressed. They also discovered that a greater surface area also means more friction and is vital for improving braking at high intensities. The combination of looking for something to squeeze and wanting high surface area led to disc brakes being adopted.

A disc brake is a mechanism for slowing or stopping the rotation of a wheel from its motion. A disc brake is normally made of cast iron, but in some cases, it is also made of carbon or ceramic composites. This is linked to the wheel and/or the axle. To stop the wheel, friction material in the form of brake pads is forced against both sides of the disc. Friction caused on the disc wheel will slow or stop.

Some discs have modifications to make sure that they cool down quicker and remain more effective. This is often achieved by letting air in, so modifications like a hole in the middle, small gaps around the outside, or fins will allow air to access the disc and ultimately mean a more efficient braking system.

Brake Pads

Regardless of whether it is a disc or a drum your car uses, the main component that is contained within the disc or drum is a brake pad (sometimes referred to as a ‘shoe’). These are what create the friction. Many different materials are used for brake pads, but some common pads might be either organic (using glass, kevlar, carbon etc.), ceramic, semi-metallic, or fully metallic. All of the materials used are designed to absorb as much heat as possible.

Organic brake pads are very quiet and don’t wear down the disc, but they do need to be changed more frequently as they tend to be worn down.

Ceramic pads are also very quiet, last a long time, and have a great braking capacity, far better than organic pads.

Semi-metallic pads surpass even the capacity of ceramic pads, but because of the metallic flakes in the synthetic material they wear down the disc more, so that the brake disc will need to be changed more often.

Finally there are full-metal brake pads. These are what race cars use. They have an incredible stopping capacity, but are noisy and will wear down the disc like an ice cream melting in the sun. Your car is likely to contain synthetic or ceramic brake pads and these are both fine choices for everyday driving.

Mechanical braking systems

Mechanical brakes were the first of the braking system types installed on motorcars when they were mass produced in the 20th century. These systems involved a series of pulleys, cables, cams, and other devices in order to apply friction to the brake drum and bring the car to a stop. When the pedal was depressed it would pull on a cable, the ‘brake line’, which in turn forced the drum to press onto the wheel and bring the car to a stop.

There were many problems with these braking systems. For one, they required a huge amount of maintenance as the brake lines and all other moving parts had to be kept in perfect condition for the brakes to work. When the brake cables came under too much pressure or the force required to bring the vehicle to a stop was too great, they could also snap easily and this would be very dangerous. The systems also needed maintenance because of how precise they had to be; if a lever was off or the tension in the wires was not quite right, different wheels would receive different braking pressures, making the car very difficult to control.

Because of all of these problems, by the end of 1950s mechanical brakes were rarely seen on cars and they were replaced with hydraulic brakes.

Having said that, most cars still do have a form of mechanical brakes: the handbrake. As well as having main hydraulic brakes, cars often have a mechanical handbrake that uses a lever and an arm in the brake drum to help stop the car. They are operated by a cable from the handbrake lever inside the car. A ratchet on the handbrake lever keeps the brake on once it is applied. A push button disengages the ratchet and frees the lever. All cars have a handbrake system (sometimes it can be electric not mechanical) that acts on two wheels – usually the rear wheels. This mechanical system is only really meant to secure the car when parking rather than bring it to a stop, so a mechanical system is suitable.

Hydraulic braking systems

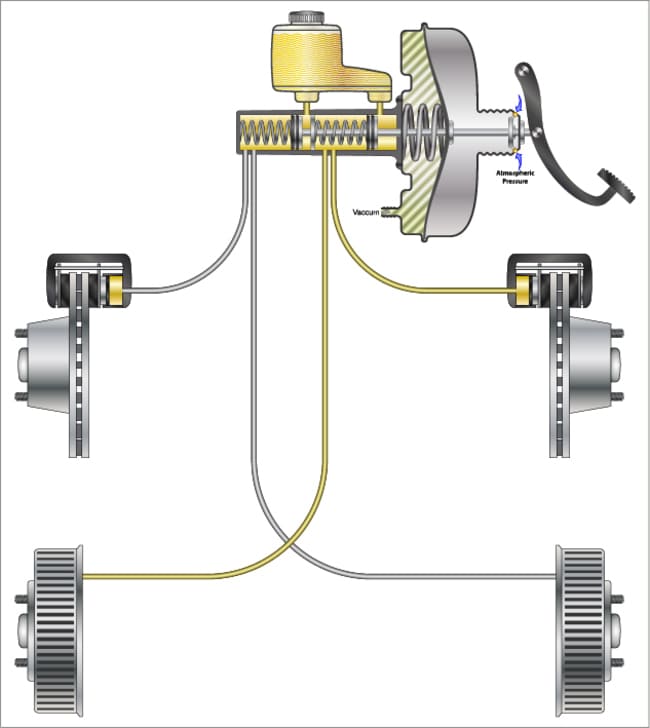

The most common brake system for modern cars is a hydraulic braking system and your car almost certainly has hydraulic brakes. Cars commonly have this on all four weeks and hydraulic systems can either use a brake disc or a brake drum.

Unlike older mechanical braking systems, hydraulic systems use fluid to apply pressure on the brakes. Hydraulic fluid is stored in brake lines and is used to transmit pressure or force from the brake pedal or brake lever to make the car stop. Brake fluid, or hydraulic fluid, is a non-compressible substance that can operate under high temperatures and high pressure.

In this type of braking system the mechanical force comes from the driver pressing on the brake pedal. This force then pushes the brake fluid through the lines and, since it is non-compressible, towards the brake system. In a device known as a master cylinder this force is then converted into hydraulic pressure that is sent to the brake calipers or drum shoes (depending on the type of system).

Each brake caliper has a series of pistons contained within it (up to 6) and the hydraulic pressure forces the caliper to clamp shut on the disc or drum. The brake pads attached to the brake caliper create friction when they rub against the brake disc or drum and this is what ultimately brings the car to a stop.

There are some distinct positives to hydraulic braking systems too.First, the force generated in the hydraulic braking system is higher when compared to the older, mechanical braking systems that used to be used in cars. These are rather primitive and rely on levers, linkages, or cams, which do not transfer as much of the force as the hydraulic braking systems. Mechanical systems can also lose their effectiveness over time as the working parts break down.

The chance of hydraulic brake lines rupturing is very low and they require very little maintenance, again as opposed to mechanical brakes. They are also incredibly quick and responsive to the pedal and it requires very little force being applied to the brakes to exert pressure on the drums or discs.

Since a hydraulic system has far fewer moving parts than a mechanical system, wear and tear of these parts, and any associated or resulting maintenance, is also reduced. This makes the system cheaper and more reliable than a mechanical one.

Since mechanical systems could also greatly differ in their design and construction from car to car, this made repairs often tricky. Hydraulic systems have a relatively simple design and are easily assembled, making maintenance easier.

Servo braking system

Often also referred to as power-assisted brakes, or a brake or vacuum booster, a servo braking system is designed to give extra power to reduce the effort needed to apply the brake and will work in conjunction with hydraulic brakes.

The brake servo works by creating a partial vacuum, which then increases the force applied to the main cylinder. With a brake servo, the brake pedal first presses an attached rod, which then allows air to enter the booster while closing the vacuum. Pressure then increases on the rod that connects to a rod inside the master cylinder.

The brake servo has become more common in cars as disc brakes have replaced drum brakes as the standard setup in vehicles. Disc brakes make it necessary for cars to have power brakes to remove a majority of the force that a driver needs to exert to stop the car.

Inside the brake servo system, a vacuum multiplies the force that is exerted by the driver on the brake pedal. The outward appearance of a brake servo is a canister that contains a diaphragm, a valve and is usually constructed from metal. Attached to the brake servo is also a check valve, which limits the direction of air to outward only in order to eliminate the risk of losing brake function while the car is operating.

If the vacuum fails because the engine stops, for example the brakes still work because there is a normal mechanical link between the pedal and the master cylinder. But much more force must be exerted on the brake pedal to apply them.

Comment