Brake pads are important elements of the brake system, on which the safety of all road users depends. Therefore, their choice needs a responsible approach. We will tell you what to look for when buying.

Types of brake pads

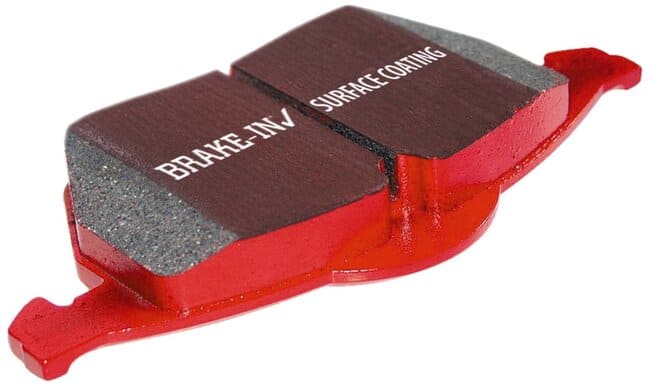

Brake pads consist of a backing plate and a friction lining, for the production of which over ten components can be used.

The composition of semi-metallic brake pads includes at least 65% of metal. The remaining 35% are a mixture of graphite and inorganic materials. The advantage of this pad type is the ability to efficiently withdraw heat, the drawback is their excessive hardness, which leads to premature wear of the brake disc.

Low steel brake pads are made of organic materials with the addition of metal (no more than 30%). They have a good heat conductivity and provide more efficient braking. They cost almost twice as much as semi-metallic pads.

Kevlar, glass and carbon are the basic materials for manufacturing organic brake pads. Composition of these components includes no more than 15% of metal. They are soft and silent in operation, but are subject to wear more than other pad types, therefore they are not suitable for aggressive driving fans.

The composition of ceramic brake pads includes ceramic fibers, synthetic rubber and non-ferrous metals. Such pads provide a steady friction coefficient, they are less abrasive. They are the best choice for sports driving style. They are more expensive than other brake pad types.

Categories of brake pads

All pads can fall into two categories:

- original;

- analogues.

The advantages of original brake pads are obvious, but they cost twice as much as analogues. They are sold in original packaging, made by a trusted manufacturer.

High quality analogues are only slightly inferior to the original spare parts by their characteristics. These pads are cheaper, while providing quite sufficient braking performance. However, there are analogues made of substandard materials. Usually such pads are not properly tested and do not meet generally accepted standards. It is important to avoid a mistake when choosing the parts: too low price should alert you.

The main parameters of the brake pads

1. Perating temperature. Brake pads resistant to temperature of 300-350 ° C should be sufficient for city driving and a moderately fast ride. Sports cars are equipped with brake pads that operate at a temperature of 900 °C, but they ensure an effective braking only when heated above 100 °C.

2. The friction coefficient. Pads with the friction coefficient of 0.25-0.35 are enough to stop the vehicle at a moderate driving.These are the values that non-original components usually have. The coefficient of friction of original brake pads is slightly higher, about 0.3-0.5. Sports brake pads at the operating temperature of 150 °C have a low coefficient of friction – 0.2. When they are heated, it can increase up to 0.5.

3. Service life. The part’s wear resistance depends on the material of which it is made. A soft friction lining wears out faster, but a too hard one leads to premature abrasion of the brake disc.

Tips for choosing brake pads

How to distinguish an original part from a fake

1. Pay attention to the presence of the certification mark. If you do not see R90 or 90R written on the label, that’s a fake.

2. The package must contain a product passport, a warranty certificate, a certificate of quality, and an installation guide.

3. The surface of original brake pads should be smooth and uniform.

4. Check the part’s unique code number at the manufacturer’s website.

The best manufacturers of brake pads

The leading manufacturers of brake pads are:

- Brembo;

- Ferodo;

- Bosch;

- ATE;

- TRW;

- STARK;

- Textar;

- Lucas;

- Jurid;

- Remsa;

- PAGID.

The products of these companies vary in price and operating characteristics. The companies Brembo and Ferodo produce brake pads for sports cars. The parts from the ATE company are also capable to withstand operating temperatures up to 800 °C.

Brake pads from the TRW, Lucas, Bosch, Remsa and STARK are more suitable for everyday city driving. They have slightly lower parameters, but are significantly cheaper. The PAGID company manufactures products for luxury cars.

The American company Jurid produces pads that are used as original parts by automakers, but can also be supplied as an analog for vehicles of other brands. Products of this company are also known under the brand names BendixR, FRAMR and PrestoneR.

Please note: when choosing brake pads, it is important to consider not only the popularity of a brand, but also specific features such as your driving style and conditions of the vehicle usage. Only by taking into account all of these details, you can choose the components that will provide a long and reliable operation of your car.

Comment