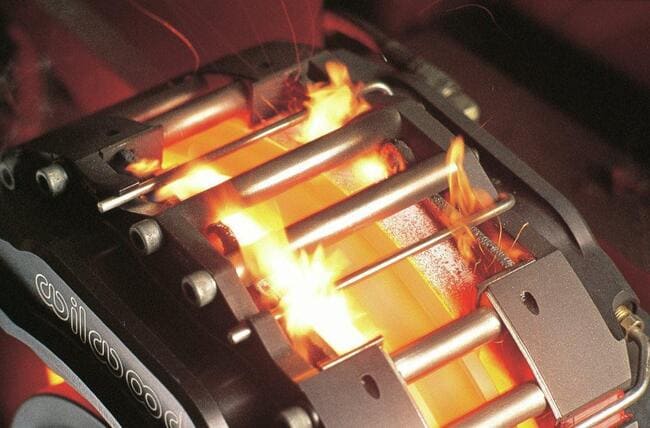

One of the most common brake disc defects is overheating. In case of overheating, the disc temperature reaches critical values, causing the brake pad to slip on the disc and reducing the efficiency of the brake system to a minimum.

How to detect the brake disc overheating

The brake disc overheating can be determined by the part inspection. Steel is the most common material used to manufacture brake discs. When heated, the material changes its color. A steel disc, heated to the critical temperature, becomes bright orange and after cooling gets a purple color.

If the visual inspection reveals a color change of the brake disc, you should immediately contact a service station for a complex diagnosis. After detecting the fault, the replacement of brake discs and pads is mandatory. This procedure can be carried out by self. Our detailed video guides will help you do it.

The causes of the brake disc overheating

How to prevent overheating of the brake discs

To prevent premature wear of the brake discs and ensure the most efficient braking process, AutoDoc recommends the following:

- replace the brake pads and discs in due time;

- install high-quality components;

- entrust the repair work to service station mechanics if you lack experience;

- replace the discs in pairs by the axle set for load balance;

- during prolonged downhill movement exercise engine braking;

- monitor the brake disk thickness.

Let us remind you that the useful life of the front brake discs is 30 000-40 000 km, and of the rear ones is 40 000-50 000 km. These values depend on the driving style. Aggressive driving with sharp acceleration and braking reduces the useful life of the brake discs.

Comment