Rotary engines are combustion motors that operate without the need for pistons. This topic concerns those used in cars, often called rotary combustion motors to tell them apart from certain types of early aircraft and motorcycle engines. There are multiple different designs for this type of propulsion, but most use at least one rotor or rotary piston to create locomotion from fossil fuel combustion. The only such motor to see widespread use is the Wankel engine.

Difference between rotary and piston engines

Between the two types, piston engines are by far the more commonly found motor. They use aforementioned pistons to compress a fuel-air mixture and then ignite it, forcing the piston back and creating rotational motion in the process. These motors use two or four strokes for this process. Two stroke engines compress and ignite the fuel every time the piston extends, allowing the exhaust to escape as it is pushed, completing two strokes for every one complete rotation of the crankshaft. Four stroke variants ignite the fuel much like two stroke variants do, but only ignite the fuel-air mixture once every two rotations of the crankshaft. This second extension of the piston instead pushes exhaust out of the engine. Four stroke engines burn more cleanly than those only using two strokes, as the latter allow fuel to escape alongside the exhaust. Two stroke motors in turn have fewer moving parts, are less vulnerable to wear and tear, and have a high power-to-weight ratio.

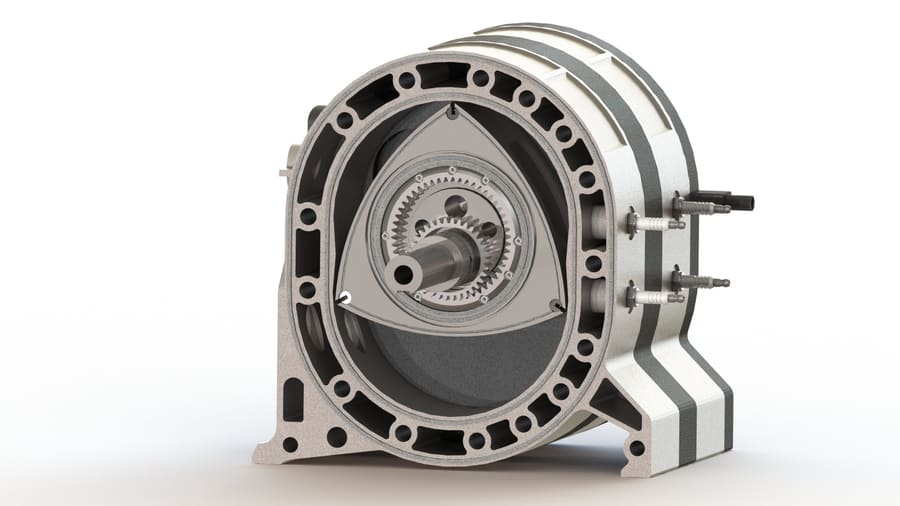

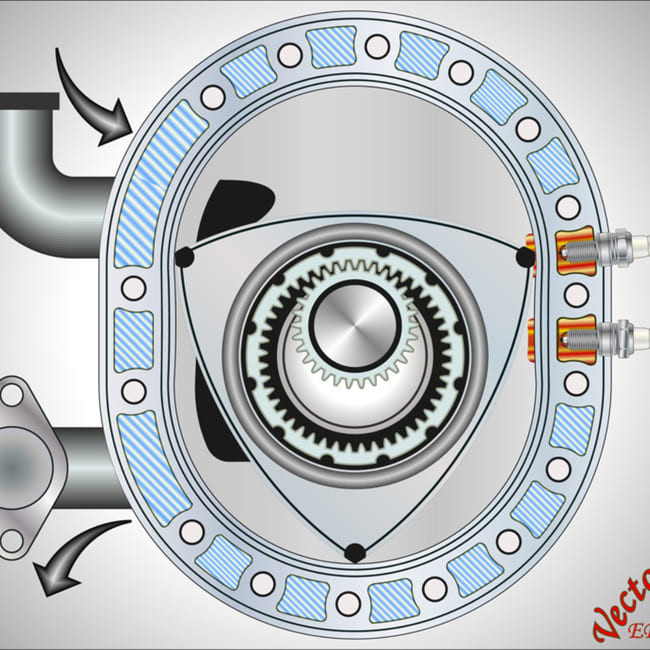

Wankel engines operate completely differently, but resemble two stroke engines most in their operation. Instead of pistons, Wankel rotary engines use a triangular rotor. This rotor has sides that curve outwards. Unlike motors with pistons, this rotor simultaneously draws in fuel, compresses the fuel-air mixture, and removes exhaust gases. This is possible because the corners of the rotor separate the oval housing into three combustion chambers, one for intake, compression and ignition, and exhaust. There are no strokes to speak of since the entire work occurs in one fluid motion. Wankel motors enjoy a particularly high power-to-weight ratio, since they are able to perform three power pulses per revolution while two stroke engines achieve only one and four stroke engines only one every two revolutions. Attempts to create a diesel rotary engine based on the Wankel design have been attempted, but have never advanced beyond the prototype stage.

Advantages of rotary engines

Wankel motors are superior to piston engines in a number of areas. Primarily this is because of their significantly higher power-to-weight ratio as well as the relative compact size. This makes them particularly useful for small vehicles or machinery. They also contain fewer parts, making production and maintenance simpler. There is no noticeable vibration when they are running, making their operation smooth. They are also resistant to engine-knock.

Disadvantages of rotary engines

These motors do have a few drawbacks though. For one, sealing the chambers is tricky since the housing is subjected to temperatures that vary significantly while still consisting of the same material. The design also makes accurate lubrication impossible, resulting in a higher oil consumption than with piston engines. Petrol-fuelled motors also run into issues with emissions. Because of how the fuel-air mixture is burned, unburned petrol can escape during the process, leading to worse emissions or the use of an inefficient fuel-air ratio to mitigate this. This has a lot to do with how petrol burns somewhat slower in the long and thin chamber. Overall, many of these downsides are an issue when rpm are low and are mitigated by high speeds or loads.

Applications

Due to their unique characteristics, there are a number of different ways Wankel engines have been implemented. While the most obvious application is in small-scale, motorised machinery such as chainsaws, there are also some cars with rotary motors.

Tools and subsystems

The small size and lack of vibration make the rotary engine well-suited for power tools like chainsaws or auxiliary power units. The latter are particularly prevalent in aircraft. Other implementations include lawnmowers.

Racing cars

Due to them being better suited for higher rpm, rotary motors find application in automobile racing. Mazda has developed engines for this purpose and earning success in the 24 Hours of Le Mans. Particularly the Mazda 787 series uses this type of motor.

Motorcycles

Their excellent power-to-weight ratio is an asset to motorcycle construction, where space is at a premium. The issue these designs often run into, however, is their unique cooling needs. Nevertheless, the companies Yamaha, Kawasaki, Hercules, Suzuki, Van Veen, and Norton built motorcycles with motors based on the Wankel engine design since the German manufacturer Motorenwerke Zschopau presented the first one in 1960. However, the complications involving the design have resulted in most of these being dropped for their poor profitability. No new Motorcycles with these kinds of motors have been manufactured for sale to the public since 1992.

Aircraft

Aeroplanes are perhaps some of the vehicles for which the rotary engine is best suited. Light and compact propulsion with a high power-to-weight ratio are a must for powered flight. The lack of vibrations is also extremely beneficial. The engine seizing or suffering engine-knock is also far more disastrous in a plane, so the elimination of the risk of these happening is a relief to any aircraft manufacturer and especially any pilot. One major drawback, namely the issues the motor has at low speeds or before being warmed up, is mitigated by running it while the plane undergoes the preflight check before take-off.

Other vehicles

Small vehicles such as snowmobiles, jet-skis, and go-karts make use of rotary engines. Again, the compact size with a high power output is what makes it viable for such systems. There are even motors for vehicles as small as model aircraft weighing only 380 g. The perhaps most outlandish use of a Wankel motor is in the American M1A3 Abrams main battle tank, which makes use of the additional power such a motor packs to move its exceedingly large weight.

Comment