Modern automobiles often prize comfort and luxury alongside speed and performance. People tend to think of heated seats or cruise control systems as adding comfort to a journey, but the biggest factor in ensuring that every ride is as smooth as it can be? Suspension. A car’s suspension system is without a doubt the most important factor in having a comfortable and steady performance and allowing the driver to truly control their car. But what is the purpose of the system, aside from providing comfort, and how does it work?

The function of suspension systems

The main job of a car suspension system is to ensure that there is maximum friction between the tyres and the surface of the road, to provide steering stability with good handling, and to ensure the comfort of the passengers. It is inten to absorb vibration, gravitation, and impact forces from the road.

If every road were completely flat, with no bumps, pot-holes, or irregularities, suspension systems wouldn’t be necessary. But sadly this isn’t the case anywhere in the world. Even freshly paved streets have tiny imperfections that can interfere with the wheels of a car and how it is running. These imperfections apply force to the car, pushing it upwards. The magnitude of the force, of course, depends on how large the open that has been hit is. Either way, the car wheel experiences a vertical acceleration as it passes over an imperfection. It’s the job of the suspension system to deal with these upwards forces and ensure that the wheels stay on the road at all times.

If it does it’s job right and the wheels are constantly in contact with the surface of the road, then there is maximum friction and the risk of rolling or flipping the car over is minimized and it helps to make sure that power is transmitted to the wheels, where it is needed the most. The tyres absorb all the shocks and vibrations, as well as other imperfections in the road, and in conjunction with the car’s shock absorber mechanism as part of the suspension, the effects of these shock forces can be effectively dampened. It is technically the spring mechanism of modern suspension systems that pushes the tyres into the ground so that we have maximum friction and the best ride possible. So when a tyre hits a bump or is forced upwards because of something in the road, it’s the suspension system that pushes the tyres back onto the ground and keeps the car as stable, safe, and comfortable as possible.

Components of a suspension system

Before we come to look at the different types of suspension and how they work, it’s important to have a basic understanding of the key parts of almost all suspension systems.

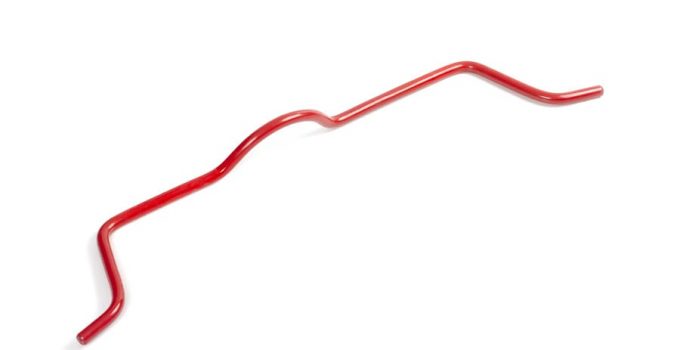

The key components of a suspension system are springs, dampers, and anti-sway bars. To reduce it to the very basics, the springs absorb the force of impact, the dampers then work to dissipate this energy, and the sway or anti-roll bars are used alongside the dampers to give the automobile additional stability when driving. An anti-roll bar is a metal rod that spans the entire axle and joins each side of the suspension together.

Springs

There are of course several different types of springs, dampers, or sway bars. Leaf springs are one of the oldest forms of suspension springs. These springs are essentially several layers of metal bound together to act as a single, slender, arc-shaped unit. They are attached to the axle and as the car hits a bump or irregularity in the road, the layers compress together to absorb the shock. Though these are much less common for cars nowadays, they can still be found on heavy goods vehicles and trucks in the USA.

The most common spring component of a suspension system are coil springs. A coil spring is a heavy duty torsion bar coiled around an axis. How stiff the spring is affects how the sprung mass (everything located above the springs and therefore supported by the springs) responds when the car is driven. If there is very little tension in the spring, it is ‘loosely sprung’, it’s likely to be a very smooth ride. Luxury cars, for example, are often loosely sprung. They can, however, be prone to dive and squat during braking and acceleration and have a greater body sway or roll during cornering. Tightly sprung cars, on the other hand, give less when they hit bumps, so it can be uncomfortable, but minimize body motion so they can take corners aggressively, ideal for a sports car.

A common feature in European vehicles is a system involving a wishbone or an ‘A’ control arm. This is made up of a torsion bar attached to a ‘wishbone’ arm (so called because it is shaped like the V-shaped ‘wishbone’ from a turkey’s neck) and to the vehicle’s frame. The wishbone acts like a lever that moves perpendicular to the torsion bar, when the wheel hits a bump vertical motions transfer to the wishbone or control arm and then through the levering action to the torsion bar. The torsion bar then twists along its axis to provide the spring force.

Dampers

When springs absorb the force and energy from uneven surfaces in the road, this energy must be dissipating somehow. This is the job of dampers. Shock absorbers are, therefore, a type of damper. They slow down and reduce the magnitude of vibratory motion by turning kinetic energy into heat energy to be dissipated through hydraulic fluid. Shock absorbers are velocity sensitive; the faster the suspension moves the more resistance the shock absorber provides. They can adjust to road conditions and control all unwanted motion including bounce, sway, break dive, and acceleration squat.

Struts are a more advanced form of damper and are essentially a shock absorber mounted in a coil spring. This simultaneously functions as a dampener like a shock absorber and structurally supports the vehicle’s suspension – they do more than shock absorbers as they support the weight of the vehicle to a certain extent. Struts are very common in front suspension in front-wheel drive vehicles.

Types of Suspension

Various combinations of spring systems and dampeners can be found in different vehicles and the type of suspension used can even vary within vehicles – the front suspension suspension system is likely to differ from the rear suspension system.

A suspension system can be either dependent and independent. In a dependent suspension system a rigid axle binds two wheels together, whereas in an independent system, the wheels are permitted to move independently and are not joined together. Older cars tended to favour dependent suspension systems, often in conjunction with leaf spring coils, but more modern cars favour independent suspension systems, particularly for the front suspension. Dependent systems are strong and simple, but because there is no camber adjustment when cornering, there is a risk that wheels can come off the surface of the road. As for independent suspension systems, shock loads from the surface of the road are isolated to the side on which they are encountered, which is hugely advantageous. Of course, whether the system is dependent or independent will affect what form of springs and dampers can be used.

Often, front and rear suspension in cars will be different. Front suspension systems need to be integrated with steering and therefore can be quite complex and they are also the first to come into contact with any foreign bodies or uneven surfaces on the road. Rear suspension systems can often be simple because steering doesn’t need to be taken into consideration. This means they’re often dependent systems (see below for an explanation), based on a leaf spring or a coil spring. If all our all wheels have individually mounted suspension, then the car can be referred to as having four wheel independent suspension.

Double Wishbone Suspension

The double wishbone suspension is made up of two wishbone shaped (A or V shaped) arms positioned on top of one another. They are hinge-mounted to the top and bottom of the vehicle knuckle to provide vehicle steering and to balance the wheel. Shock absorbers are often attached to each control arm and this type of suspension gives more control over the camber angle of the wheel to minimize roll and sway and provide for a more consistent steering feel. These are popular on the front wheels of larger cars, which might be heavier and prone to rolling or swaying in corners. Though it is lightweight and has a lot of advantages, it is also more costly that solid beam (dependent) suspension systems.

Short/Long arm Suspension (SLA)

The short/long arm suspension is a modification of the double wishbone suspension that can be used on both the front and rear wheels of automotive vehicles. In the double wishbone suspension the two arms are of equal length. In a short/long arm (SLA) suspension, the two arms are of unequal length; the upper arm is shorter than the lower arm. This design helps to control camber and limit tire edge wear when taking corners. The length of the upper arm is made shorter so that, when cornering, with centrifugal force tending to roll the vehicle and putting tires on their edges, this suspension system acts to move the contact pattern back to the centre of the tyre for both wheels. This effect takes place all the way to full jounce making it an ideal suspension for performance vehicles. The coaxial spring and shock absorber can be mounted on the lower arm for non‐drive wheel systems and on the upper arm for drive wheel installations.It is often found on the wheels of a rear drive vehicle with a front inline mounted engine.

MacPherson Strut Suspension

This system comprises a single control arm in a strut assembly which allows the tyre and wheel to move upwards and downwards. This lowers unsprung mass and increases driving comfort. It is small, relatively inexpensive, and not too complicated which means that they are a popular choice of strut. On some of the same vehicles, a strut is also used in the rear suspension system. It is similar to the front strut but does not have the anti‐friction bearing at the top because of being on a non‐steerable wheel.

Adjustable and Hydraulic Suspension

Along with all the basic types of suspension systems manufacturers offer as standard, many drivers opt for adjustable suspension systems which they can fit, adjust, and maintain themselves. These can also be provided by some manufacturers as standard in new cars. Some suspensions allow adjustment by the driver or automatically by the car itself and these can help to deal with certain conditions. In effect, a car with an adjustable suspension can take on the function of two or more slightly different suspensions, depending on what the situation is.

Two main parameters can be adjusted with adjustable suspension systems: ride height and ride stiffness. High-end cars can sometimes come equipped with the ability to raise and lower their bodies as the situation dictates, The Tesla Model S is a good example of this as it automatically raises itself when being driven into entrances like car parks or driveways. Some SUVs can be set to a lower suspension height on smooth roads, for stability and economy, or higher when driving off road, for increased ground clearance.

Ride height adjustment normally uses airbags built into the springs; changes in the amount of lift correspond with any changes in air pressure. Other manufacturers use hydraulic systems to accomplish the same thing, with pumps supplying hydraulic pressure to help lift the vehicle.

Some vehicles provide active suspensions that automatically stiffen the ride when a driver is maneuvering at high-speed; they make this happen using a pneumatic (air) or hydraulic (fluid) reservoir with varying pressure. Ride stiffness adjustment is incorporated in aftermarket systems that feature adjustable spring rates and/or shock absorber performance. Most of the time, making adjustments like these mean physically getting under the car and changing something manually, most commonly a dial on the shock absorber that changes the shock’s tendency to dampen movement. Systems that can be adjusted from inside the car are much less common.

Dedicated race cars go even further than these two systems, allowing adjustment of almost every aspect of the suspension. A skilled race mechanic can adapt a race car to each individual track.

Adjustable height suspension nowadays is becoming more commonly offered by the manufacturer, as concern about fuel economy grows. When cars are lower, they become more aerodynamic, and therefore more fuel efficient. The other types of adjustable suspensions listed above are found primarily in aftermarket systems (must be added after the manufacturing process), particularly in adjustable shocks and “coilovers” (systems comprising a coil spring and an associated adjustable shock or strut). But in any case the intent of an adjustment to the suspension is the same: incorporate a change to help adapt to different needs or conditions.

Comment