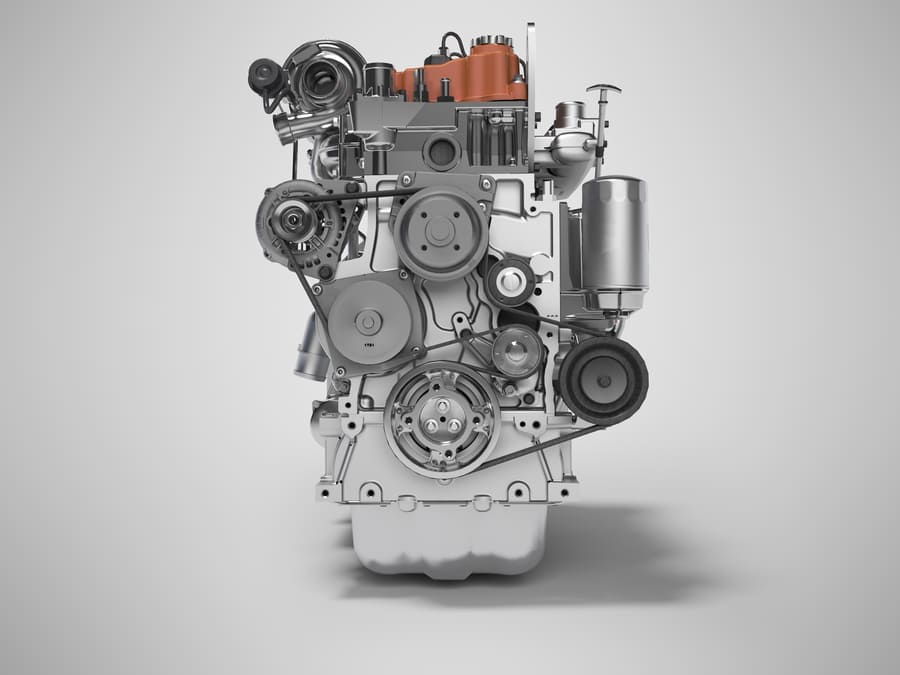

A car engine is the main unit that powers a vehicle. It consists of hundreds of interacting parts. Engine lubrication ensures that enough oil is supplied to the lubrication points of the combustion engine in all operating conditions. Here you will find information on the workings, components, and maintenance of this system.

Function of the lubrication system

Any engine will quickly fail without proper lubrication. Its function is a combination of several factors which do the following:

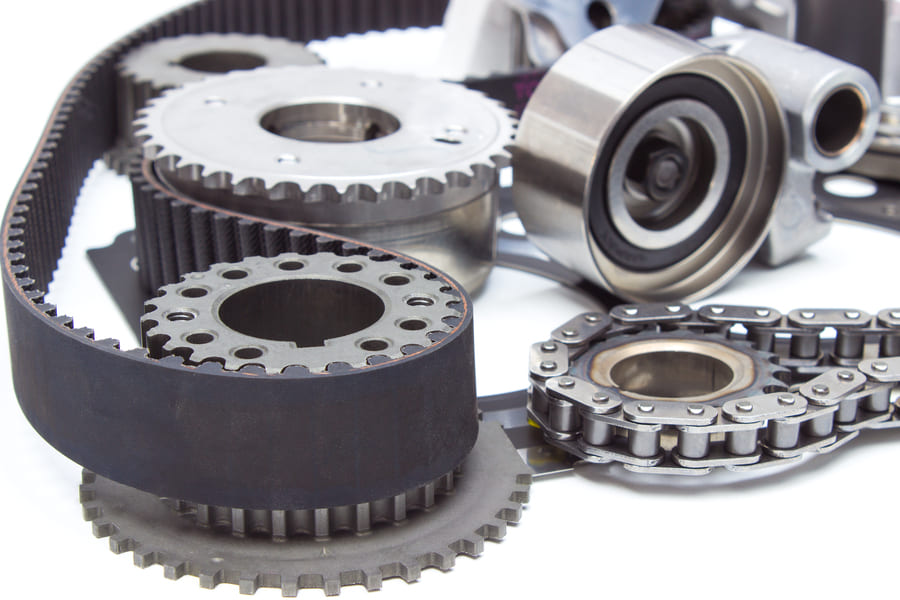

In some car modifications, oil is an operating fluid for adjusting hydraulic jacks, timing belt tensioners, and other such systems.

Types of lubrication systems

Pressure – an oil pump creates pressure in the oil line. Spraying or centrifuging – in this case the parts rotate, as in a centrifuge, and spray oil over the entire cavity of the mechanism. It is then deposited on the components and then gravity causes the remainder to flow back into the reservoir. Mixed – this is most commonly used in modern car engines. Some components of the engine are supplied with oil using pressure, others by spraying. All systems are divided into two main categories:

Wet sump

The lubricant is located in the pan below the crankshaft. The pump draws in the oil and transports it through channels to the lubrication sites. The rotation of the crankshaft provides additional circulation and cooling of the piston. The remainder is then collected in the reservoir. The drawback is that through the running of the engine, the lubricant may begin to foam up and splash, causing the engine to run low on oil. Although the sump is at the bottom of the engine, due to the large volume, the oil still does not have time to cool down. If the pump is placed in a downward position, it will not draw in enough lubricant and cause the motor to overheat.

Dry sump

Here, the lubricant is kept in a separate tank and transported to the lubrication points by the main oil pump (pressure pump). In contrast to pressure lubrication, the oil is drawn out of the sump by means of a second pump (suction pump), and pumped back to the reservoir. The advantages of the more complex dry sump system are:

The disadvantage of a dry sump system, however, is that it is much more costly than pressure lubrication. It also includes more parts that could easily break. This is why it is mostly used in sports cars, motorbikes, or off-road vehicles. In comparison to pressure lubrication, the oil level must usually be read when the engine is running.

Most common parts/structure

How does it work?

The operating mechanism works as follows: as soon as the engine starts, the pump starts working automatically. It supplies oil through the filter, through the cylinder head channels, to the most highly strained parts of the engine – the bearings of the crankshaft and the camshaft. Other control components are lubricated through grooves on the main bearing of the crankshaft. The oil flows, by means of gravity, along the grooves in the cylinder head into the sump. This closes the circuit. At the same time as the lubrication occurs, oil seeps through the holes in the connecting rods and then sprays onto the piston and cylinder wall. Heat is now drawn away from the pistons and the friction on the cylinder o-rings is reduced.

Operation and maintenance

The efficiency of this system depends on its service-life and must be maintained regularly. A careless oil, or filter change can lead to costly repair. In some cases it would be cheaper to buy a new vehicle than to overhaul the entire engine. Therefore it is important to familiarize yourself with the instructions provided in the manual. Many drivers rely too heavily on mileage, but this isn’t necessarily an indication that you need to change your oil. The fact is, that even if your car is running while stuck in a traffic jam, the oil will slowly lose its lubrication properties. To ensure that your lubrication system continues to function properly, make sure that you keep an eye on it, and the oil levels necessary to keep your car running for as long as possible.

Comment