It seems to you that your vehicle accelerates slower than usual, and overcomes hills with difficulty? Do not rush to look for faults in the ignition or fuel supply: if these symptoms are accompanied with free play of the clutch pedal, and unpleasant burning smell is felt in the passenger compartment from time to time, the problem is likely to be clutch slipping. We will explain why it occurs, and how to avoid it.

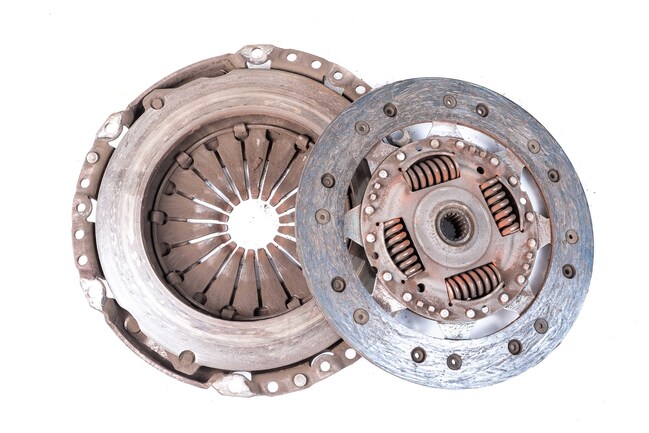

Clutch slipping: where the problem is

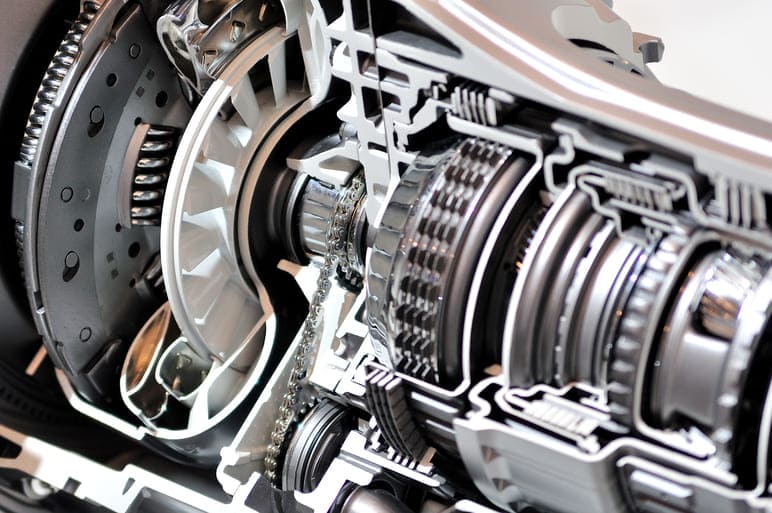

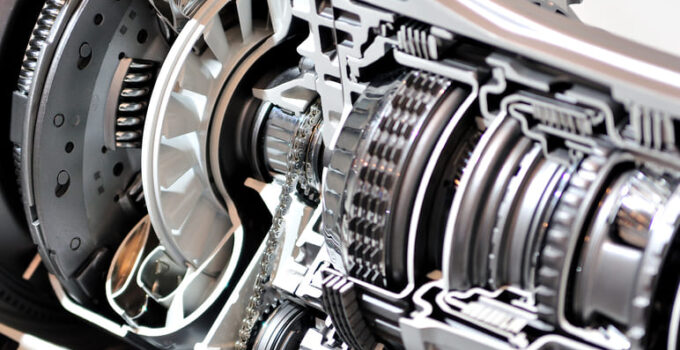

Correct operation of the system depends on the friction force between the driven disk and the flywheel. If the friction coefficient reduces for some reason, the contacting surfaces start slipping, and the torque is not transmitted completely from the engine to the transmission. As a result, vehicle acceleration to certain speed requires more time, and its performance deteriorates. It also becomes more difficult to overcome climbs and hills, since the power transmitted to the shaft of the gearbox is not sufficient for moving the vehicle.

5 most common reasons of clutch slipping

- Worn, damaged friction linings and disc surface. Excessively worn friction linings, due to reduced thickness, are not pressed strongly enough to the surface of the flywheel. The mechanism compression effort is not sufficient to provide fixed connection of its elements. A deformed lining is unevenly pressed against the flywheel.

- Oiling of friction linings. It contributes to reducing its roughness. Due to the low friction coefficient, the contacting elements slip.

- Weakened or damaged diaphragm spring. If spring elasticity has decreased, the pressure exerted on the driven disc by pressing the pedal will be insufficient to activate the unit.

- Malfunction of the clutch linkage. Stretched cable, damaged fork in vehicles with mechanical clutch, swelling of rubber components, or loss of tightness in elements in vehicles with hydraulic actuation may also result in clutch slip, since the pressure effort on the diaphragm spring is not sufficient to ensure fixed contact of the mating parts.

- Damaged wear compensation mechanism. Due to malfunction of the adjustment ring or the sensor spring, clearance adjustment becomes impossible. This reduces the hold-down pressure of the driven disc.

6 recommendations that will help avoid clutch slipping

- Try to replace components of the system in a kit. The average service life of the pressure plate and the driven disc, the diaphragm spring and the release bearing is about the same, approximately 100,000-150,000 kilometers of mileage. Therefore, to make the system work as long as possible, always replace components in a kit.

- Check tightness of vehicle components and assemblies. Poor-quality or damaged gaskets of the engine and transmission, oil leaking from the input shaft oil seal or the crankshaft seal, loss of tightness of the hydraulic actuator are the reasons of friction linings oiling.

- Choose components depending on your driving style. A standard clutch with friction linings made of composite material will be fine for calm and smooth driving. They have the optimum coefficient of friction, low operating temperature, and are inexpensive. However, a sports car should better be fitted with special clutch designed for heavy loads. Its linings are made of materials with addition of carbon and Kevlar, and from a mixture of copper, aluminum, cast iron and ceramics. It withstands much higher temperatures, has increased wear resistance, and is suitable for aggressive driving.

- Check correct adjustment of pedal travel. Insufficient pedal travel prevents complete disengagement of the clutch. This causes accelerated wear of the friction linings, and may be the reason of overheating and warping of the driven disc.

- Always use the working fluid recommended by the manufacturer. Do not mix fluids different by composition. Aggressive compounds formed as a result of mixing, or components contained in the particular class of fluids may be destructive to the hydraulic clutch actuator.

- Stick to the following rules of clutch operation:

- when pulling off, first loosen pressure on the pedal so that the car starts off and begins moving slowly, then hold it in semi-pressed condition for 2-3 seconds and only then release it completely;

- do not pull off at high RPM;

- going down a steep hill, engage the first gear, from time to time pressing the brake pedal to avoid overheating of the components.

- when getting out of difficult off-road areas, for example, a puddle, a snow pile or mud, use a tug if possible;

- When driving, do not rest your foot on the clutch pedal continuously to avoid involuntary pressing it;

- do not overload your vehicle, especially when driving on poor quality roads: this greatly increases the load on the unit.

Conclusion

Clutch slipping is a common failure, which makes driving not only uncomfortable, but dangerous, too. But in most cases, any car owner can prevent problems. Just buy high-quality components and adhere to the above recommendations.

Comment