Basically, the definition of a car clutch is that it is a crucial mechanical device that links and separates the engine’s power from the transmission, enabling smooth gear changes. This means that it is an essential component of manual transmissions, serving as the intermediary between the engine and the wheels.

What is a clutch in a car?

A clutch is a mechanical device that separates the output shaft from the rotating input shaft. Typically, the input shaft of the clutch is connected to a motor, while the output shaft is connected to the working mechanism. By pressing the clutch pedal, you interrupt this connection, allowing you to shift gears without grinding. When you release the pedal, the engine and transmission are reconnected, letting you accelerate.

What does the clutch do?

A clutch separates the transmission from the engine, allowing smooth gear changes or keeping the car in gear while waiting to move off. When you come to a stop with the car in gear, the clutch is used for disengaging the engine, preventing the car from stalling. In addition, when starting off, the clutch slips slightly at the friction point to gradually engage the engine, ensuring a smooth start without stalling. This makes the clutch an essential component for controlling power transfer in manual gearboxes.

If your clutch isn’t working properly any longer, you may need a replacement clutch kit.

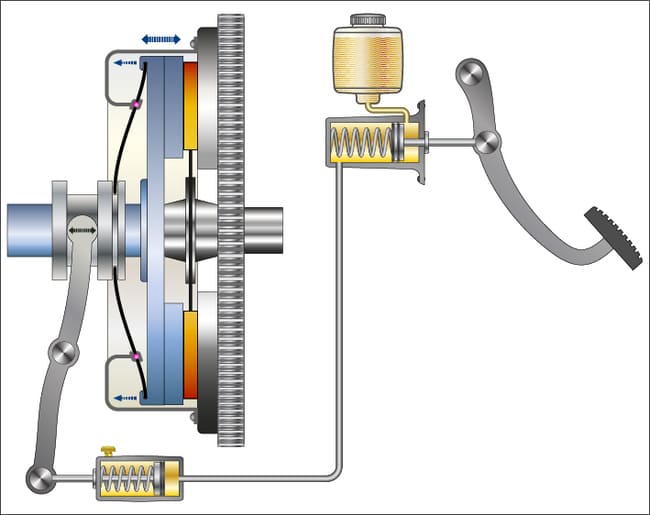

How does a clutch work?

A clutch is what connects and disconnects the engine from the transmission in a vehicle, allowing the engine to engage and disengage smoothly. It’s a friction disc sandwiched between the engine’s flywheel and a pressure plate. When you press the clutch pedal, the pressure plate pulls back, separating the friction disc from the flywheel, thus disconnecting the engine from the transmission. When you release the pedal, the pressure plate re-engages the friction disc with the flywheel, transmitting power to the transmission. This mechanism lets you change gears without stalling the engine, and it makes starting and stopping the vehicle easy.

For further information, you can find diagrams of a clutch system in various automotive repair manuals, educational websites, and online articles about automotive engineering.

Different types of clutches

There are different types of clutches, each one designed for a specific purpose:

Friction clutch:

- Uses friction between a clutch plate and a flywheel to transmit power.

- The most common type, found in most manual transmission vehicles.

Multi-plate clutch:

- Features multiple friction discs for greater power transmission.

- Common in high-performance vehicles and motorcycles.

Centrifugal clutch:

- Engages automatically at a certain engine speed.

- Typically used in scooters and chainsaws.

Hydraulic clutch:

- Uses fluid pressure to operate.

- Offers smoother engagement and disengagement.

- Common in modern vehicles with manual transmissions.

Electromagnetic Clutch:

- Activated electrically.

- Used in various machinery and automotive applications, including air conditioning systems.

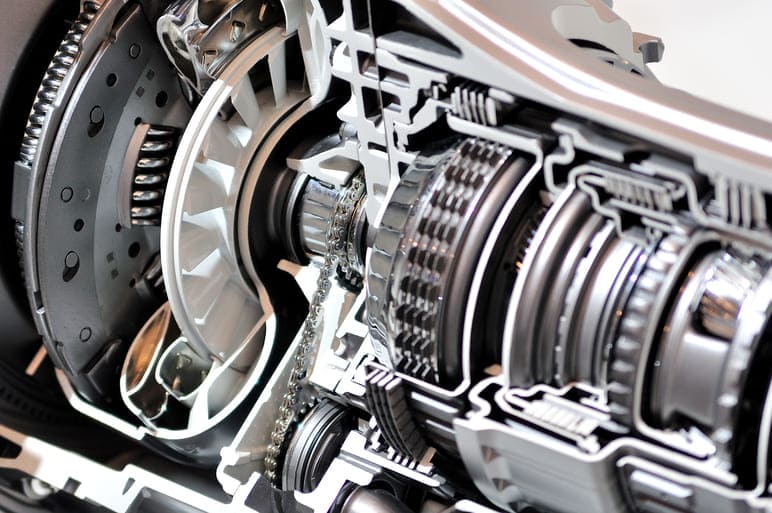

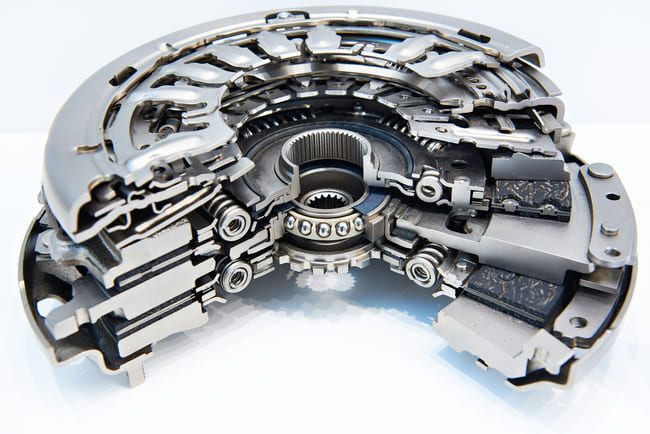

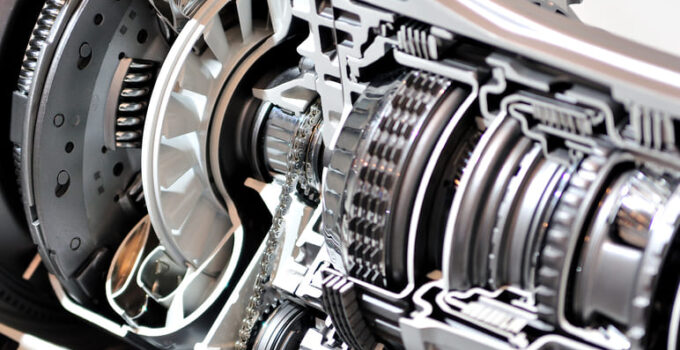

Clutch components

A clutch system is made up of several key parts:

- Clutch flywheel

The clutch flywheel is a heavyweight disc, often made of cast iron, that spins with the engine. It acts like a bridge between the engine and transmission. One side provides a smooth surface for the clutch disc to grip onto, transmitting power. The other side has teeth that mesh with the starter motor, cranking the engine to life. By storing rotational energy, the flywheel helps smooth power delivery from the engine, especially during gear changes.

- Clutch pressure plate

The clutch pressure plate, a key player in manual transmissions, clamps the clutch disc to the flywheel. Imagine a metal disc with powerful springs inside. When you press the clutch pedal, a mechanism squeezes these springs, forcing the pressure plate away from the flywheel. This releases the clutch disc, stopping power transfer and allowing gear changes. Upon releasing the pedal, the springs push the pressure plate back, clamping the disc and flywheel together to resume power flow.

- Clutch disc

The clutch disc, the heart of gear changes, is a flat disc faced with high-grip friction material. It sits between the flywheel and the pressure plate. When engaged, the disc’s friction lining connects with the flywheel, transmitting engine power to the transmission. During gear changes, you press the clutch, disengaging the disc from the flywheel. This allows the engine speed to adjust independently before the disc re-engages, enabling smooth gear transitions.

- Clutch release mechanism

The clutch release mechanism translates your clutch pedal press into action. Think of it as a lever system with a release fork at one end. When you press the pedal, a hydraulic line or cable pushes the fork. This pivots, pushing a release bearing against the clutch diaphragm spring. The bearing’s pressure flexes the spring, momentarily separating the pressure plate from the disc, interrupting power flow and allowing gear changes.

How long does a clutch last?

It is estimated that a clutch will typically last between 30,000 and 100,000 miles, with 60,000 miles being a common midpoint. The lifespan of a clutch is dependent on several factors, including driving habits and vehicle type.It is important to note that city driving with frequent stops and starts will result in faster wear of the clutch than highway cruising. Furthermore, the effects of high temperatures can also accelerate the rate of wear. The ease of use of the clutch is also a significant factor. It is important to avoid riding the clutch pedal and to learn to make smooth gear changes to maximise the clutch’s lifespan.

How do you know if your clutch is going?

Watch out for these 5 signs that your clutch might be wearing out:

- Difficulty shifting gears: If you experience grinding noises when trying to shift, especially from a stop or into reverse, it indicates the clutch disc isn’t fully disengaging.

- Burning rubber smell: This is a telltale sign of clutch slippage. This happens when the worn clutch disc struggles to grip the flywheel, causing friction and burning.

- High engine revs: The engine revs climb high when you press the gas pedal, but the car hesitates to pick up speed.

- Clutch pedal feels different: A well-functioning clutch pedal should have a firm and consistent feel. If it feels spongy, soft, or vibrates when pressed, it could indicate hydraulic issues or internal wear in the clutch mechanism.

- The bite point is all over the place: If this point feels like it’s constantly changing, higher or lower than usual, this signifies clutch wear.

Take a look at How to detect clutch failure for more information.

Car Clutch FAQs

Where is the clutch in a car?

The clutch in a car is usually found between the engine and the transmission, right behind the engine’s flywheel. It’s a key part of the drivetrain, allowing the engine and transmission to work together smoothly for gear changes.

What pedal is the clutch?

The clutch is the leftmost pedal in a car with a manual transmission. It’s used to disengage the engine from the wheels when changing gears or coming to a stop.

What is a clutch kit?

A clutch kit is a set of parts that replaces the worn friction components in a car’s clutch, typically including the disc, pressure plate, and release bearing.

Comment