What are turbochargers? How do they work?

In simple terms, a turbocharger, also known as a “turbo”, is a type of air compressor that is powered by a turbine and used to boost the power of an engine without significantly increasing the weight of the power unit. It does this by compressing the engine air flow, forcing a higher amount of air into the cylinders. By helping the cylinders to take in more air, it allows more fuel to be burned in the combustion chambers, thus increasing the horsepower. Additionally, by using gases to increase the output, it reduces the vehicle’s carbon emissions.

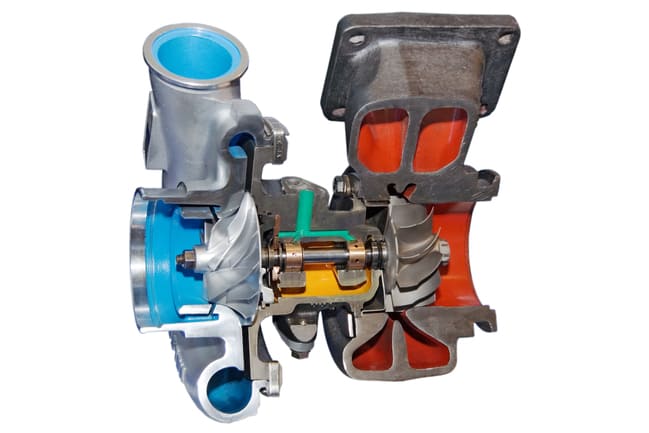

The turbocharger is mounted to the engine’s exhaust manifold. Its turbine spins when the exhaust gases from the cylinders flow through the mechanism, which actuates the air pump. The more exhaust flows through the turbine, the faster it spins, reaching speeds of up to 150,000 rotations per minute. A shaft connects the fan component to the air compressor, which pressurises the air that is supplied to the pistons.

Additional turbocharging system components

Turbo types

- Single-Turbo

This is one of the most common types as well as the most affordable. They vary in size which means that their torque characteristics also vary, however, they have limited RPM ranges. Larger mechanisms provide more top-end power, whereas the smaller ones are faster but better for providing low-end power. Turbo lag is also a frequent problem for this type of turbocharger. - Twin-Turbo

These systems include two turbocharging mechanisms. For example, one can be added to each cylinder bank in V6 or V8 engines. Another method known as sequential turbocharging involves installing one low RPM single mechanism and one high RPM mechanism to extend the unit’s range. However, installing two components makes it more difficult to maintain and increases the associated costs. - Twin-Scroll Turbo

The turbine housing is designed differently with a scroll that is divided into two parts, creating two paths for exhaust gas. One path will be connected to a different set of cylinders to the other path. This way, the air is delivered more efficiently and it has a higher density. - Variable Geometry Turbo (VGT)

These expensive mechanisms are often used in diesel engines. VGTs feature aerodynamic vanes inside the turbine housing that can adjust the air-to-radius ratio to match the RPM of the motor. This means that at a low RPM, the ratio is low to increase the exhaust gas velocity and pressure, allowing the turbo to spool more effectively. At high revs, a higher ratio increases the airflow. - Variable Twin Scroll Turbo (VTS)

VTS systems combine features of twin-scroll and VGT mechanisms for greater efficiency at a lower price. For example, at low revs, one of the scrolls is closed off by a valve, forcing the air into the other scroll. The valve adjusts the airflow according to the engine speed. These systems are also suitable for petrol-powered vehicles. - Electric Turbo

These devices are used to tackle turbo lag and assist conventional turbochargers when operating at lower revs. The electric motor powers the compressor when the car starts moving and when the airflow is not strong enough. This system is much more efficient in this regard but, at the same time, more complex as the electrical components also need to be powered and cooled.

How do I know if my turbocharger is working properly?

All car parts stop working eventually, turbocharger parts included. It is important to know the symptoms of a bad turbo, so that you can respond quickly and prevent further damage.

Common symptoms:

Comment