Electric cars are becoming a more and more common sight on the road. Powered by electric motors that don’t require combustion to function and powered by battery packs, they are quiet, low on emissions, and efficient. They have benefits that are progressively outweighing their disadvantages, making them a more attractive option for drivers across the world. But the devices they use to propel themselves forward; are those even engines? In this post, we will explore what an electric motor is, what makes it tick, what types can be encountered on the open road, and whether you can refer to it as an electric car engine.

Motors and engines

Motors and engines are treated as the same thing nowadays and have been for quite some time. You would have to dig all the way to the Latin etymology to find a difference other than the spelling. However, in the automotive industry, the term “motor” is used to refer to any device that creates motion by converting energy into mechanical energy. An “engine” by contrast is a motor that specifically uses thermal energy. So while there isn’t really any difference in day to day English, the terms do differ in usage in the car industry. By this definition, all engines are motors, but not all motors are engines.

The real difference is the means by which the electric car’s motor works when compared to that of a petrol- or diesel-fuelled car. Petrol and diesel vehicles use internal combustion engines. Most commonly these involve the use of cylinders that generate motion through an ignition of a fuel-air mixture. This drives a piston which then rotates the crankshaft. Since the electric motors in cars use electric currents instead of combustible fuel, they function completely differently and aren’t considered engines in this sense.

While there are different types of electric motors, the basic principle of how they work is the same: In order to convert electric energy into mechanical energy, the electric current is supplied to a stator. This is a device that remains fixed in place and creates an electromagnetic field when powered. Within the stator is a rotor, a rotating part which the electromagnetic field induces to turn. This torque is then transferred to mechanical gears, achieving the same effect as the piston pushed by the combustion in internal combustion engines does. Interestingly enough, electric motors can also convert mechanical energy into electricity, which comes into play when slowing down.

Different types of electric motors

Electric motors may use alternating currents (AC) or direct currents (DC). The former has electricity that flows in both directions while DC only flows in one direction. Electric motors in cars typically require AC while their batteries supply DC. The current supplied to the motor must therefore be transformed with an inverter to be of any use in generating mechanical energy.

These AC motors come in two main variants: asynchronous and synchronous motors:

Asynchronous motors. These motors work as described above, using a stator that acts as an electromagnet. The rotor essentially attempts to catch up to the electromagnetic field without ever succeeding.

Synchronous motors. These motors operate on a different principle. The rotor helps create the electromagnetic field together with the stator. This leads to the rotation speed being dependent on the current flowing to the motor.

Due to their construction, synchronous motors work well for driving in conditions with frequent stops and variable speeds. Asynchronous motors are better suited for lengthy driving at higher speeds or smaller devices.

Parts of the electric motor

Electric motors are complicated bits of machinery with many important parts. They invariably have some form of magnet to get the rotor to rotate in the first place, but these may come in different forms. Electromagnets, as described above, are common, but some synchronous motors have permanent magnets as well, using ferromagnetic rare earths. These have the advantage of not requiring a power source to function, but run into supply issues regarding the materials used to make them. Electromagnets have the benefit that their functionality can be precisely controlled through increases and decreases in the voltage they receive.

Where the stator is an electromagnet, it consists of a coil of copper winding around an iron or aluminium core. The powered coil is referred to as a field coil or field winding.

The rotor usually consists of steel or other metals.

How does an electric motor work in a car?

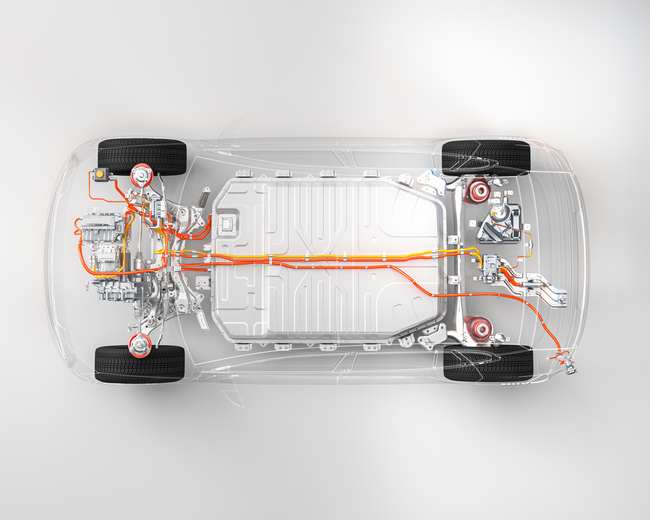

While an electric motor can stand on its own, in order to provide locomotion for an electric vehicle, it is usually integrated into a larger unit: the electric powertrain. The electric powertrain consists of a charger, a battery pack, a DC-AC converter, and the electric motor.

The charger is hooked up to a public charging station or the mains and converts AC electricity flows into DC in order to charge the battery pack. Occasionally, charging stations provide direct currents to forgo the need for the converter to become active in the first place, thus speeding up the charging considerably when compared to charging the vehicle from a private outlet at home. The batteries, usually lithium-ion cells, store energy to be used for the system and pass this on to the DC-AC converter. The converter turns the battery pack’s DC energy into AC, so that the synchronous motor receives the necessary voltage to function. The motor then connects to the vehicle’s drivetrain, converting the torque generated by the stator and rotor into mechanical energy that is transferred to the axles and thereby the vehicle’s wheels.

Comment