From bags to life to separating our rubbish, recycling is great. So good in fact, even your engine recirculates and reuses gas from the combustion process.

With climate change continuing to shape the world around us, governments are taking action. For the everyday car user this often means problems. Car manufacturers are being forced to lower exhaust emissions even further than they have done in the past 20 years due to even more stringent legislation. Diesel and gasoline manufacturers are doing as much as they can to catch up with e-cars and hybrids and comply with the new emission standards.

One of the ways that conventional, fuel-based engines are trying to achieve this is through exhaust gas recirculation (EGR) systems. The ingenious system helps to reduce the amount of nitrous oxide – one of the most harmful bi-products of the combustion process – that comes out of your car’s exhaust. On gasoline engines, the system also reduces fuel consumption when the engine is operating under partial load. But what exactly is an EGR system, how does an EGR valve work, and what are some common EGR problems? If you’re exhausted from searching for answers to these questions, look no further!

What is the exhaust gas recirculation system?

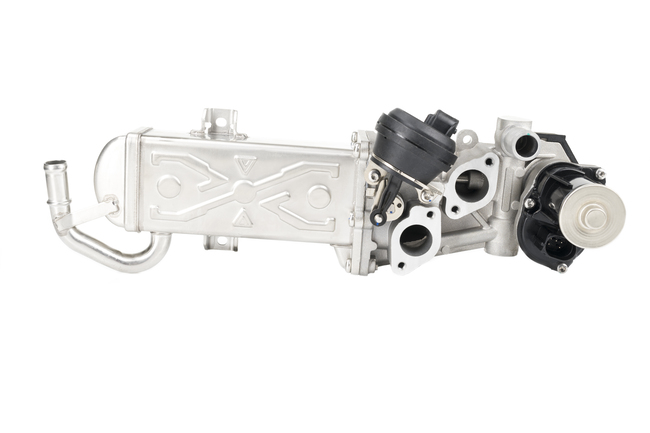

Put simply, the exhaust gas recirculation system (EGR) reduces NOx emissions in internal combustion engines. The system is made up of an EGR valve, a temperature sensor, and a control unit and it is connected to both the ECU and the intake/exhaust manifolds in the engine.

The main purpose is to reduce these NOx (nitrous oxide) emissions and it does this by recycling exhaust gases back into the combustion chamber, where it cools the combustion. The gases that have already been used in combustion don’t take part in the next combustion process, but they still help to reduce NOx and also the temperature of the chamber itself.

Part of the reason for wanting to keep the temperature of the chamber low is that if the combustion temperature is high it can lead to the engine overheating and also more nitrogen oxide being produced in the engine’s combustion chamber. The combustion temperature in the combustion chamber is reduced by recirculating a portion of the exhaust emissions back to the fresh intake air and the lower combustion temperature results in less nitrogen oxide and an engine that is less likely to overheat.

How does the system work and why do you need it?

As part of the combustion process, air enters the combustion chamber through the intake manifold and mixes with the fuel. As it is compressed or ignited (depending on the system), the pressure forces the piston down to power the engine and exhaust gas comes out through the exhaust manifold. If an engine is working at full-load, meaning it is working at its greatest capacity, when accelerating hard for example, this process works perfectly and all of the oxygen atoms in the air that are taken in from the intake manifold are used in the combustion process.

What normally happens though, is that an engine is working at only partial load. When you are just driving along the road, idling, or searching slowly for a parking space, the engine isn’t operating at full capacity, what we refer to as partial load. This becomes a problem with regards to emissions. Because less fuel is injected (because the engine isn’t required to work as hard) not all of the oxygen atoms are used in the combustion process. The leftover atoms combine with the nitrogen (that makes up 70% of the air that enters through the intake manifold) to form NOx (nitrous oxide). Unfortunately, this is a toxic atmospheric pollutant and is exactly what the new governmental legislation is designed to avoid. This is where the EGR comes in.

In the final exhaust stage of the 4 stroke combustion process, as the exhaust gases leave the cylinder, the exhaust gas is partially rerouted internally and pumped back round towards the combustion chamber. Before it gets there, there is an exhaust gas recirculation valve. Where the egr valve is depends on your car’s system, but it is always before the intake manifold so that it can regulate how much gas is recycled.

The gas already used in combustion combines with the fresh air that is also going into the chamber and the gas which then enters the chamber is a combination of gas already used in the combustion process and fresh air. The value regulates how much of this gas is allowed in.

Working with the ECU, sensors determine the load on the engine, i.e. how much power is required from the engine, and the amount of exhaust gas that is recirculated is calculated accordingly.

The lower the load, the more exhaust gas is recycled as there will be less fuel injected into the cylinder and therefore more harmful NOx by-product.

If the load is higher, more fresh air and oxygen is allowed in and so less exhaust gas is recycled. Since the gas that has already been used is inert (it doesn’t react) there is no risk of it reacting with the oxygen to produce more emissions.

The temperature of the gas also has an impact on the combustion process and has another advantage. Since the exhaust gas is warm, it decreases the time it takes for the gas in the cylinder to hit the temperature required to exert pressure on the piston and therefore gets rid of ‘ignition lag’. In short, it makes the engine function more efficiently and faster, offering a more controlled combustion.

As stated above, this process also decreases the temperature of the combustion process. Compression gases raise the temperature which is needed to apply pressure on the piston. But the inert gases absorb this temperature because they are at a lower temperature than the compressed gas. Heat is absorbed by recycled gases and means that there is less NOx by-product and a lower chance of the engine overheating.

What are some common EGR problems?

EGR is used continuously with the engine and so the system is subjected to very high loads, which can cause problems, particularly on vehicles with high mileage. Since the value is the most important part of the system here, most of the problems are associated with this.

It is fairly obvious if there is a problem with your EGR value because your car will experience bad EGR valve symptoms like rough idle and stuttering when acceleration. Your fuel economy will also go down thanks to a faulty EGR valve and you may see a check engine light on the dashboard followed by a readable code in your car’s OBD-II or newer computer.

The likely causes of these symptoms will be a blocked EGR valve. A build-up of deposits in the EGR valve over a period of time causes the valve to let less or no recycled gas through which will mean your car’s performance will start to suffer (the ECU will assume that the right amount of gas for combustion is in there, as it assumes the valve is working). This happens especially often with a diesel EGR valve. This build-up is part of the ordinary operation of the vehicle and can be fixed either through cleaning or replacing the valve.

EGR valve cleaning isn’t as tricky as you might think and you can definitely do it yourself. Once you have located and removed your EGR valve (the location will vary from vehicle to vehicle, so check your user’s manual), shake it lightly. If you hear something moving back and forth inside, that’s the diaphragm—which means there is a good chance that your EGR valve is still good and just needs to be cleaned to return to normal function. If you don’t hear anything, your EGR valve might be blocked. This isn’t a definitive test, but it is a good place to start.

If you have a newer EGR valve, it is likely to be electronic and therefore will have a wiring harness connected to it. In this case, it is important that you avoid getting corrosive cleaners on the wiring and connectors and of course the engine needs to be off as well. You’ll also need reliable eye protection and chemical-resistant gloves.

Cleaning an EGR Valve

First remove the vacuum line, which is the rubber line connected to your EGR valve. If it is brittle, broken, frayed, damaged in any way, or otherwise seems less than perfect, replace it. Vacuum problems are the source of all kinds of engine woes, including a faulty EGR valve.

Next disconnect the Electrical Harness and unbolt the EGR Valve. If it doesn’t come right off when you have removed the nuts or bolts, you can loosen it by giving it a tap with wood or a small hammer.

Remove the gasket next and check to see that it is okay and isn’t torn, frayed, or disintegrated. If it doesn’t look so fresh, you can install a new one at the same time.

Cleaning the valve assembly is a two-step process. First, soak the valve itself in a bowl filled with carb cleaner. Carb cleaner smells horrible and is nasty stuff, so soak it outside or in a very well-ventilated area. Let it soak overnight if you can. If this isn’t possible, skip to the next step.

Once you’ve let your EGR valve soak in cleaner overnight (if possible) you need to clean its passages, openings, and surfaces with a small brush. Toothbrushes and pipe cleaners soaked in the same carb cleaner you used before are great for this. Make sure you use your eye protection and gloves at this stage to avoid injury. You want to clean as much as you can out of the valve and get in as many different nooks and crannies as possible – the more black sediment you get out of there the better your chances of fixing the problem.

Once it is clean and crust-free you can reinstall your clean EGR valve. Don’t forget to reattach your vacuum hose and your electrical connections if you need to. If you are still experiencing problems once you have cleaned the valve, you may have to replace it.

Comment