What is an alternator belt?

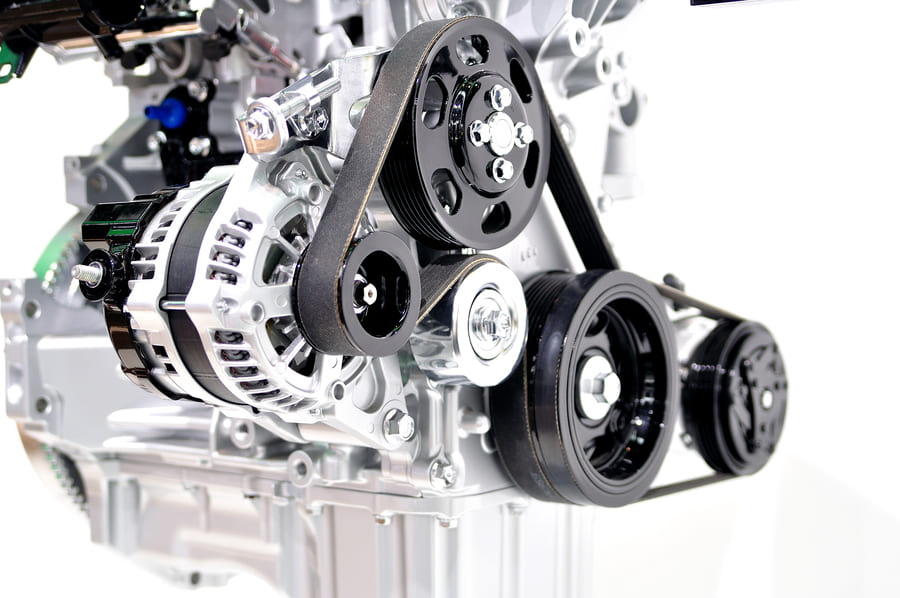

The car alternator is essentially a power generator which keeps the car battery charged and allows it to continuously power the key electrical components of the car. Without this, the battery would be drained quickly as it does not have the power to supply electricity to all of the components for extended periods. The alternator is attached to the engine by brackets and bolts. It is powered by the crankshaft mechanism and driven by a belt.

In the past, the alternator was driven by its own separate drive belt, which wrapped around the crankshaft and alternator pulleys. Nowadays, the large majority of vehicles use one belt, known as a serpentine belt, to drive multiple units, including the alternator, power steering pump, water pump, air conditioning system unit.

Ribbed belts are designed to maintain as much contact with the pulleys as possible to increase the power transmitted. If the belt gets damaged, these units will stop working and, as a result, the car’s power system could shut down.

What does an alternator belt do?

An alternator belt transfers mechanical energy from the engine’s crankshaft to the alternator, enabling it to generate electricity. It ensures the alternator operates efficiently while the engine runs.

A properly functioning belt maintains consistent tension and grip, which is essential for reliable electrical output. If the belt slips or gets stretched, the alternator may fail to charge the battery effectively, leading to electrical issues and potential engine performance problems.

Causes of alternator belt problems

Bad alternator belt symptoms

Here is a list of the most common symptoms to help you identify when your belt needs to be replaced due to frequent slipping, wear, or looseness.

Why your alternator belt makes noise

An alternator belt may get noisy due to wear, insufficient or excessive tension, or misalignment. Common sounds include squealing or chirping, especially during startup or acceleration. A loose belt can slip, while an overly tight one may strain components.

Dirt, oil, or ageing rubber can also cause slippage and noise. Regular inspection and timely replacement help prevent damage to the alternator or engine accessories and ensure smooth, quiet operation.

Why is my alternator belt squeaking?

If your car’s alternator belt is making a squeaking noise, this is often because there is not enough tension in the belt, causing it to slip on the pulleys. This can happen due to stretching or a faulty tensioner. Cold weather or moisture can also cause temporary squeaks during startup.

If your belt is worn out or glazed, it may lose grip, increasing the noise. If you deal with this issue quickly, you can prevent further damage and system failure. Re-tensioning (or replacing) the belt normally fixes the problem.

Why is my alternator belt screeching?

A screeching drive belt is often more serious than a simple squeak. It may be a sign that the belt is slipping badly due to extreme looseness, a failing tensioner, or a seized pulley.

High engine loads, like running the AC or power steering, can make it worse. Oil or coolant leaks can also reduce traction. Ignoring the screeching may lead to belt failure or serious engine damage, so a prompt inspection is essential.

How to check the alternator belt

Here are the basic steps to check your alternator belt and ensure it’s in good working condition:

- Turn off the engine and let it cool down completely.

- Open the bonnet and locate the alternator belt, usually a serpentine belt on the front of the engine.

- Inspect the belt for wear such as cracks, fraying, or glazing (shiny spots).

- Press down on the belt midway between pulleys to check tension; it should deflect slightly (about half an inch).

- Listen for squealing noises while the engine is running, indicating looseness or wear.

- Replace if damaged or excessively loose.

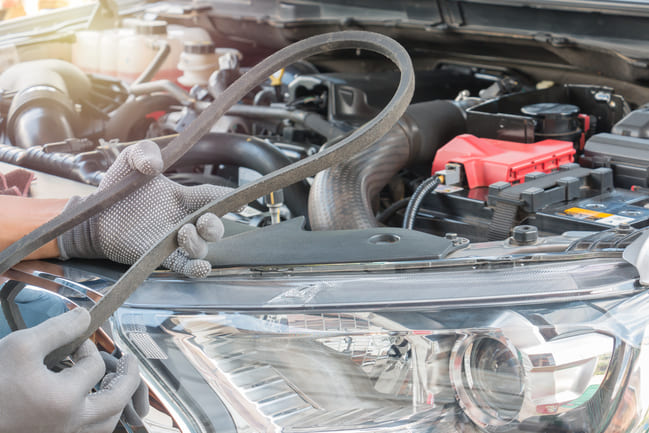

ATTENTION! When handling the belt, use protective gloves. Refer to the vehicle owner’s manual for detailed instructions.

What happens if the alternator belt breaks while driving?

If the alternator belt breaks while driving, your vehicle will lose its ability to charge the battery. This can lead to electrical failures, including dimming lights, malfunctioning electronics, and eventually, engine shutdown once the battery drains.

In many vehicles, the alternator belt also drives other components like the coolant water pump or power steering. If these stop working, it can cause overheating or a sudden loss of steering assist, making driving dangerous. Don’t continue driving if this happens.

Can you drive without an alternator belt?

Driving without an alternator belt is strongly advised against. Without it, the alternator won’t charge the battery, and key systems like the cooling system may also stop working properly, depending on your vehicle’s design. This can quickly lead to unsafe situations and a dead battery. If the belt is damaged, get the car seen by a garage or mechanic ASAP.

Alternator belt replacement: how to do it

Replacing an alternator belt is manageable with simple tools, but safety is key. These are the basic steps:

- Make sure that the engine is switched and the vehicle is parked on a flat surface with the parking brake engaged.

- Disconnect the battery to prevent electrical shock (negative terminal first!).

- Let the engine cool completely before working under the bonnet.

- Locate the belt routing diagram (on a sticker bonnet bonnet/in the vehicle repair manual) or take a photo for reference.

- Loosen the tensioner pulley using a spanner or ratchet to relieve tension on the belt.

- Slide the old belt off the pulleys carefully.

- Inspect pulleys for wear or damage before installing the new belt.

- Route the new belt according to the diagram/reference, ensuring it sits properly in each pulley groove.

- Reapply tension by tightening the tensioner pulley.

- Double-check alignment and manually rotate the crankshaft to test belt movement.

- Reconnect the battery, start the engine, and check for smooth belt operation.

Always wear safety gloves and eye protection while working.

How often to change the alternator belt

V-belts typically last up to 4 years or 40,000 miles. However, new serpentine belts can last much longer and are generally easier to maintain. The average serpentine belt can last for anything between 60,000 and 100,000 miles. Belts made from ethylene propylene diene monomer (EPDM) are more durable than standard ones and can last up to 10 years before they need to be replaced.

However, several problems can emerge as the alternator belt ages. For example, it can start to fray, wear, crack, or peel, as well as become loose or misaligned. Replacing the belt in good time is the best way to prevent the system from breaking down while the car is on the road and severe damage to the driven components and car battery.

How long does it take to change an alternator belt?

Most sources agree that replacing just the alternator belt typically takes 30 to 60 minutes for professionals, depending on engine accessibility. A certified mechanic can often complete the job in under an hour, but if the space is tight or requires parts to be removed, allow up to 2 hours.

If you’re doing it yourself as a skilled hobby mechanic, give yourself more time to account for preparation, tension adjustment, testing, and unforeseen hiccups. Do not attempt to do it if unsure.

How much does an alternator belt replacement cost?

You can estimate to pay between £70 and £150 for an alternator belt replacement in the UK. However, the price will vary from model to model and depending on the local labour rates. It’s advisable to get quotes from local garages or use online comparison tools to save money. Buying your own parts could be more cost-effective if you find a compatible deal.

Can I replace the alternator/serpentine belt myself?

Of course you can. As long as you have the right tools and skills, you should be able to replace this component yourself at home.Many vehicles have accessible belt systems, making it a manageable DIY job. However, it’s important to follow your vehicle’s service manual carefully and ensure proper belt routing and tension. In many cases, the belt tensioner may also be worn or faulty. If so, you should replace the part at the same time to avoid premature belt wear or failure. You’ll also need to inspect pulleys for damage or misalignment.

- @user_178189403.08.2023 01:31Member

Do I need a new alternator if my belt broke

@Jessica_L20.09.2023 09:00Member

@Jessica_L20.09.2023 09:00MemberWithout proper diagnostics, we are not able to advise anything, please contact the specialized car services.

Comments – 2